Leftover-concrete recycling system for Waibel Frankfurt GmbH

Waibel, the medium-sized, family-run company headquartered in Gernsheim in Germany, was founded more than 70 years ago. Waibel operates and manages several plants as well as other production and port facilities with integrated sales points for sand, gravel, stone chippings, and concrete. The company performance spectrum includes, in addition, machinery and equipment for recycling used building materials, excavated earth, and bulky refuse.

Recycling solution in detail

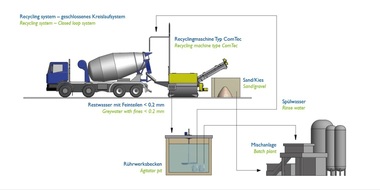

For the Waibel-Transportbetonwerk ready-mixed concrete plant in Frankfurt (Main), a Bibko ComTec leftover-concrete recycling system was installed together with a pump discharge conveyor and adapted to local conditions.

The concrete pumps can discharge easily and without delay via the funnel of the Bibko pump discharge conveyor installed at floor level. The leftover material, consisting of residual concrete and washwater, is subsequently conveyed to the downstream recycling machine.

In order to meet the requirement for minimization of flushing time, a batching buffer 5 m in length and a 7.5-m charging hopper were provided for receiving the leftover material. At the funnel, three truck mixers can flush out simultaneously, resulting in short flushing times for each vehicle and reducing waiting times to a minimum.

The material in the batching buffer is then, likewise continuously, conveyed to the wash-out and/or recycling process itself, into the ComTec Bibko recycling plant. In the plant, which has a recycling capacity of 20 m³/h, the fines content < 0.2 mm (cohesive cement and cohesive sand) is washed out. These, together with the washwater, are then conveyed to the already existing agitator basin. Built-in agitators prevent sedimentation of the fines content in the leftover water. Washed-out material > 0.2 mm is then discharged by the ComTec spiral conveyor. The water remaining can subsequently be reused for concrete production.

Positive conclusion

The above-described concept achieves a closed material circuit. The operation of a Bibko leftover-concrete plant, in addition to its economic benefits, thus makes an active contribution to the protection of the environment as well as preservation of natural resources.