Single-family house in 50-cm-thick infra-lightweight concrete

Lightweight concrete structures gain more and more attention and receive awards, like the recent Concrete Architecture Prize for a refined residence in Swabian and a notable concert hall in the Bavarian forest. If the interest that of this building material arouses in architects continues, more and more buildings may use the advantages of this lightweight concrete in the future. It has low dry bulk density combined with very good thermal insulation properties due to the admixture of porous mineral aggregates such as pumice, expanded shale, expanded clay or expanded recycled glass material. Due to its authenticity and the opportunity to build monolithically with it, lightweight concrete also matches the design ideas of many architects.

The Fiedler + Partner architecture firm in Freising has now also executed project f2 in infra-lightweight concrete without a supplementary insulation layer. As owner and designer in a personal union, he conceived the two-story residence on a plot flanked by a steep slope at the edge of the village with an open view of a building-free conservation area.

One wall – one material

The exterior shell of the ground floor consists of 50-cm-thick infra-lightweight concrete walls. The materiality of the massive walls not only stands out on the facade, but also characterizes the spatial impression in the interior. While the impression of custom formwork that alternately proj-ects and retracts due to slightly offset boards appears outside, on the inside architect Fiedler decided upon smooth formwork in which the characteristic liveliness of the concrete nevertheless stands out distinctively. On contact, the walls seem at once velvety-rough and warm. This wall does not require any installation. Different window formats allow the internal use to be read from outside. Large glazing with oak frames indicate the living spaces. A narrow, horizontal band of windows gives a hint of the kitchen area.

Like every exposed concrete building, projects with infra-lightweight concrete require construction personnel who are aware of the special care necessary in the execution. It’s good that professionals who were already familiar with concrete construction and especially building with infra-lightweight concrete were involved in the construction implementation. The Adldinger building company from Kranzberg was able to fall back on a formulation tested by experts that Heidelberger Beton had already developed in multiple tests with the participation of experts from University of the German Federal Armed Forces in Munich (UniBW).

Infra-lightweight concrete for the f2 house

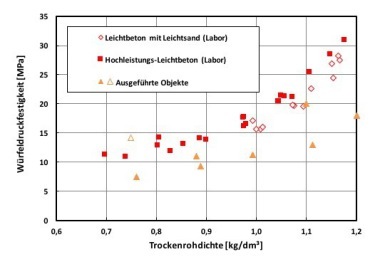

Adldinger’s concrete craftsman built the residence with a formulation that they had already used to build the Thalmair residence in Aiterbach, Upper Bavaria. With 700 kg/m³ at a compressive strength of > 8 N/mm², this highly thermal insulating infra-lightweight concrete had an even lower density than lightweight concrete. With this formulation, the degree of compactability corresponds to Class C4. In order to achieve a low thermal conductivity of λ < 0.185 W/mK, a mixture of expanded glass (Liaver) and expanded clay (Liapor) was fed into the concrete. In addition, a finely tuned system of admixtures and additives from Sika and a special cement and binding agent mixture was necessary.

The formulation was thereby matched to the expected development of hydration heat in the 50-cm thick walls. His enthusiasm for this project can be seen in architect Fiedler during a tour through the completed house, above all because of the focus on the fundamental elements; concrete, wood and glass.

Agreement in individual cases

Creative architects like Reinhard Fiedler drive the development of suitable materials for their aesthetic ideas forward with exciting proposals, demanding development of modern building materials as they do so. Architects must still currently obtain an approval in individual cases for structures in lightweight concrete with densities under 800 kg/m³ and/or a compressive strength class below LC12/13. However, that does not prevent many dedicating themselves to this building material with enthusiasm, as the growing number of notable and sometimes prize-winning buildings show.