The new DAfStb Guideline on UHPC

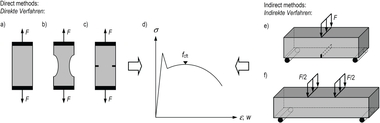

The design and construction part of the DAfStb Guideline on UHPC replicates the structure of EN 1992-1-1. The verification methods are based on the design principles for reinforced and prestressed concrete and, where necessary, account for the special structural behavior and high durability of UHPC. Modifications and amendments were required concerning, for instance, the stress-strain relationship, creep and shrinkage, required concrete cover, and maximum crack width. Extensions were also made to consider the contribution of the fibers in the design equations. The efficiency of the fiber reinforcement is expressed by the post-cracking tensile strength, which is defined as the nominal axial concrete tensile strength in the cracked state. This parameter is derived from the results of 3-point bending tests on notched beams.

In order to obtain sufficient robustness, a minimum value of post-cracking tensile strength, which depends on concrete compressive strength, is mandatory for structural components made from UHPC. The scope of the guideline thus includes structures exclusively reinforced with steel fibers as well as prestressed and conventionally reinforced structures both in combination with steel fibers.

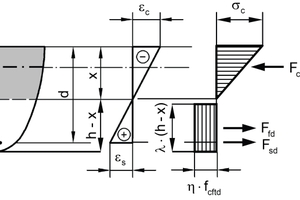

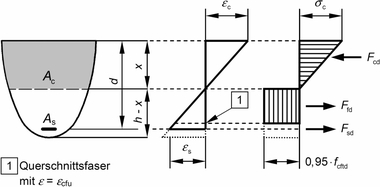

The design value of the post-cracking tensile strength fcftd is directly used in the various verifications in the ultimate limit states. The figure exemplifies the aforementioned principle for the design for bending. The contribution of the fibers is considered by a stress block in the tensile zone. The stress-strain relationship in compression is assumed to be approximately linear-elastic, which results in a linear stress distribution in the compression zone, as shown in the figure. To account for the interaction between reinforcing bars and fibers, the tensile force of the reinforcing bars Fsd is determined using a modified stress-strain curve of the reinforcing steel (not depicted in the figure).