Visual identification of material for using the right silo

Modern mixing plants allow very precise batching and documentation of formulations which are entered or recorded in the system. The filed batch records provide evidence at any time that the control unit of the mixing plant has opened the respective dosing flaps of the silos for aggregates, binders, additives and admixtures for discharging the exact amount of material from the respective silo to the downstream weighing unit.

However, until today there is some uncertainty about whether the right material had been in the right silo. In particular, as far as aggregates are concerned, which are sometimes delivered in huge quantities every day, it may occur again and again that the wrong silo is cleared for the truck supplying the material. There may be many reasons: frequently mixing plant operators must control several mixing plants at the same time, they may be distracted by telephone calls, malfunctions of the bucket conveyor, requests from the production for changing the moisture, and so on. Owing to these multitasking requirements it may occur exceptionally that even very experienced mixing plant operators, by mistake, may set the rotary distributor on top of the material silo of a tower system to the chamber of crushed sand instead of fluvial sands of the river Rhine or any other chamber. Similar things may occur with the feeding belts of a row-type silo system.

Higher costs owing to quality defects and shutdowns

Such kind of error can cause serious consequences. Generally, the fact that the rotary distributor is set to the wrong silo is not noticed directly. If this however was the case, the elevator could be stopped without any problems and the rotary distributor could be turned to the appropriate silo. However, the more likely scenario is the fact that the truck loading of sand, for instance, is discharged to another silo without noticing. Only when processing the fresh concrete, it is noticed later that the concrete has more or less coarse aggregates than the mixtures before. Normally, the production is not stopped on the first assumption directly owing to the fact that the next mixture could be normal again. If the laboratory is informed then, the laboratory worker is in the position to verify that the grading curve deviates from the formulation requested by washing out and sieving the specimen. This however would not alter the fact that concrete of a wrong mixture has already been placed in the formwork or on the production board of the precast factory. In the worst case, several building components have already been concreted with this wrong mixture. To remove the concrete from the formwork or the pallet causes a lot of effort. The complete reinforcement, including the formwork in some circumstances, has to be laid and/or produced again. If the wrongly mixed concrete, however, remains in the formwork, the result may be a concrete component with a lack of quality. To ensure a consistent quality, the precast factory would have to produce such building components affected by the wrong mixture again. The wrongly mixed aggregates have to be removed from the silo for disposing them of, meaning higher material, equipment and payroll costs as well as considerable disruptions of the production process.

In economic terms the disposal normally causes costs in the four- to five-digit range, in particular, if the shutdown is taken into account, too. It becomes even more serious if the building components of poor quality were delivered to the construction site leading to complaints, having to be replaced or leading to damages there, when being used in the construction process. In this case, the loss of image would not be even less serious for the company than the actual financial loss.

Many years of development work up to the production stage

Beton-Kemmler, the Tübingen-based manufacturer of high-quality precast concrete elements and precast parking garages, developed a solution to minimize this source of error. They found a possibility to ensure a consistent production quality by means of a neutral control unit for rechecking the decision of the mixing plant operator regarding the selection of a specific aggregate silo and stopping the feeding process immediately in case of any contradiction between the mixing plant operator‘s silo decision and the detection of the technical control system.

They were able to find a partner in Hengstmann Solutions GmbH, who managed to provide a reliable possibility to identify the different aggregates by means of an image processing system, checking the compliance with the type designation specified by the control system of the mixing plant. The greatest challenge in this regard was to distinguish exactly between the three different sand types used. For the first time, the system was integrated into the mixing plant control system of the Austrian company Simma Electronic GmbH, after several years of development work up to the start of series production.

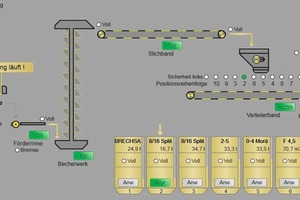

In practice, the mixing plant operator sets the rotary distributor of the respective mixing plant to the silo chamber requested as soon as the truck driver has been assigned to an unloading point. Once the driver has dumped the material into the underground silo bunker and the entire conveying systems has been started, and after a lead time set by the control system from the start of the vibrating conveyor, the selected material as well as the camera to be used is transmitted by the mixing plant control unit to the software for the identification of the gain size and started simultaneously. In order to ensure a consistent distance between material surface and camera, a wiper is used for leveling; moreover, several photos are made of the material using spot lighting for a short time.

The software, conditioned by images recorded, identifies the type of material. Afterwards the system checks whether the result corresponds to the type of the respective silo which has been selected by the rotary distributor. This process takes place before the material has arrived at the elevator. If the discharged material is identified to be the right one, the plant operator gets a message via the visualization system and feeding is continued without interruption. If there is however a contradiction between the material or silo selected by the mixing plant operator and the material identified by the system of Hengstmann Solutions, the mixing plant control unit stops transportation (by vibrating conveyor, belt conveyor or similar) of the doubtful material before arriving at the elevator. The mixing plant operator is informed and has to recheck his silo decision. Once the mixing plant operator has realized his error and has selected the right silo, there is either a new checking process after “restart” or the control system is wrong and the feeding is continued without positively rechecking (Identification “off”).

Probability of detection above 95 %

Over several months, wrong silos were deliberately selected again and again for testing purposes, and the system - with the exception of just very few cases - was able to recognized them reliably and the feeding process was stopped.

As stated by the manufacturer, the method using an image processing system developed by Hengstmann Solutions closes the gap in monitoring within the material chain of the delivered raw materials gravel, grit and sand up to the concrete component manufactured, for the first time.

For Beton-Kemmler this is a new, innovative and very important step towards ensuring the company‘s own high quality standard in order to serve the customers.

The method is convincing owing to a probability of detection of over 95 %, and it can be used for any kind of material identification in the field of aggregates. Moreover, the evaluation system is not limited to one camera or one point of identification. At Beton-Kemmler three cameras were installed in actually three underground silo bunkers and they are all evaluated by the same software.

Text: Dipl.-Ing. Rainer Spitzbarth