Automated production and accurate assembly: Challenging bridge project for OSW

Oberhessisches Spannbetonwerk GmbH (OSW) manufactured and assembled 30 prestressed concrete bridge girders up to 40 m in length and weighing almost 100 tons for the replacement of the Margaretensee bridge on the B55 federal road in Lippstadt. On-time delivery and accurate assembly of the prefabricated elements placed high demands on logistics and machinery.

OSW Spannbeton: Superior-quality structural precast components

OSW Spannbeton GmbH, based in Nidda, is a long-established manufacturer of precast prestressed concrete components with many years of experience in bridge construction, building construction, and civil engineering. OSW excels with state-of-the-art production technologies, exceedingly high quality standards, and accurate execution of sophisticated infrastructure projects. The highly automated production at its factory makes it possible to manufacture high-performance concrete components in various dimensions, aligned with the specific requirements of the respective project.

Project example: Replacement of the Margaretensee bridge in Lippstadt

A major infrastructure project in which OSW was recently involved is the construction of the new Margaretensee bridge on the B55 federal road in Lippstadt. The B55 runs in the north-south direction east of Lippstadt and is an important transport link in the Westphalian region. The Margaretensee bridge was originally built in 1959. It is used daily by about 18,000 vehicles, including 1,300 trucks. It no longer met current requirements, which is why the Straßen.NRW Sauerland-Hochstift regional authority decided to build a new bridge.

Construction began in 2023 and initially included preparatory work such as the setup of a temporary bridge and the closure of Mastholter Strasse (K34) between Lippstadt and Lippstadt-Lipperbruch. This closure was necessary to ensure safe demolition of the old structure and construction of the new bridge. The new bridge should not only improve the traffic situation but also provide increased structural capacity to cope with the growing volume of traffic in the long term.

The new Margaretensee bridge

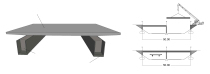

The new structure will be significantly larger than the old bridge. It will include three sections with the following dimensions:

Spans: 32.50 m - 38.00 m - 32.50 m

Total span: 103 m

Superstructure cross-section: two superstructures, each with five adjacent precast prestressed concrete elements and cast-in-place concrete infills, 8.50 m wide carriageways

Abutments and piers made from cast-in-place concrete

Foundation: deep foundation on large bored piles 1.50 m in diameter

Since the new structure will only have three sections, the height of the superstructure will be significantly greater than that of its predecessor. There will be a clearance of at least 4.50 m on Mastholter Strasse underneath the new structure, which requires the gradient of the B55 road to be raised by more than one meter. The cross-section of the B55 will also be wider in the extension area. These conditions make it necessary to widen the B55 over a length of 820 meters. Thus, additional structures will have to be erected in the extension area:

A 257 m long retaining wall will be built on the south-east side of the Margaretensee bridge between the B55 road and Margaretenweg.

Another bridge south of the Margaretensee bridge, which lets the Margaretensee drainage channel pass through underneath the B55, will be extended by installing a corrugated steel profile.

Another 27 m long retaining wall will be built on the south-west side of the new Margaretensee bridge.

Transportation and logistics: A challenge for heavy-duty haulage

Logistics contractor, Thomas Scheder, transported the massive bridge girders to the construction site. The loaded truck and trailer combinations weighed between 120 and 135 tons. Overall, heavy-duty transports traveled 19,800 km on their outward and return journeys, consumed about 19,500 liters of diesel, and were secured by 84 escort vehicles.

A last-minute change to the approved route presented the team with an unexpected challenge: A bypass was required one week prior to assembly, which necessitated a new transport permit and logistical adjustments. Nevertheless, all truckloads arrived at the job site on time and without any accidents.

Extraordinary dimensions: Installation of bridge girders

Between January 20 and 25, 2025, OSW installed a total of 30 prestressed concrete bridge girders, which weighed between 85 and 96 tons. The longest girder measured almost 40 m. In total, 975 m³ of concrete, 230 t of steel and 35 t of prestressing steel (prefabricated tendons) were used. Altogether, the 30 girders weighed approximately 2,500 t, equivalent to about 1,750 Volkswagen Golf station wagon cars. “The dimensions of this bridge project also posed a particular challenge to us. The size of the girders and the complex logistics required utmost precision and close coordination between all parties involved,” says Oliver Rühr, OSW Managing Director.

Crane-assisted installation: Heavy-duty equipment shows top-class performance

The bridge girders were installed using an 800-ton crawler crane from Franz Bracht. The crane’s technical specs illustrate the dimensions of this project:

Main boom: 84.0 m

250 t slewing platform ballast

50 t central ballast

Two carriages with 245 t suspended ballasts each to ensure maximum flexibility in load handling and assembly

Each crawler chassis weighed about 48.5 t.

A 60 m radius allowed for a lifting capacity of 100 t.

The hoist rope was about 34.0 m long.

It took 50 truckloads to set up the crane. Its ropes were positioned using an additional 250-ton truck-mounted crane to reduce the load on assembly workers and equipment.

Installation successfully completed

Installation was completed on schedule thanks to the efficient collaboration between OSW, ELO Beton, Thomas Scheder, Pontes Spezial and Franz Bracht. “Five bridge girders were installed on each day, so that the last section was successfully installed on Saturday afternoon,” says project manager Matthias Schäfer.

This project impressively demonstrates OSW’s expertise in the manufacture and assembly of precast prestressed concrete elements for major infrastructure projects – yet another example of the successful execution of sophisticated projects using state-of-the-art production technologies and planning with pinpoint precision.

Project update:

Construction of the new B55 bridge in Lippstadt came to a halt in March 2025 because contractor Karl Pollmann based in Neubeckum had filed for bankruptcy. Straßen.NRW terminated the related contracts and is now forced to put the remaining work stages out to tender again.

CONTACT

Oberhessisches Spannbetonwerk GmbH

Alois-Thums-Straße 1-3

63667 Nidda/Germany

+49 6043 807 106