Automation of prestressed hollow-core slab production at Habau Group

Modernizing and upgrading production facilities is of paramount importance for the construction industry to remain competitive and meet ever-increasing market demands. Habau Group is acutely aware of this necessity and has undertaken a comprehensive overhaul of the prestressed hollow-core slab production line operated at its Perg precast plant. Building upon many years of experience in producing precast elements, it was time to replace the old line with a state-of-the-art, automated solution. This investment leads to significant improvements in terms of efficiency, quality, and cost savings.

Precast plant upgrade in Perg

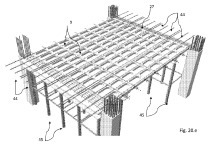

The Perg precast plant is an important part of Habau Group, a family-owned company employing about 6,700 people. Although the Perg site is only a small part of the overall corporate structure with 170 staff, it is one of the largest and most modern precast plants in Austria. It produces prestressed hollow-core slabs, column base blocks, columns, beams, wall panels, and other precast elements primarily for the industrial and commercial construction sectors. The Perg plant focuses on supplying major projects such as furniture stores or logistics centers, some of which require up to 50,000 m² of floor slabs.

Why the upgrade?

The decision to upgrade the production line primarily stems from the technological progress seen during the past decades. “After 40 years in service, our old production line was simply outdated,” explains Manfred Karl, Habau Group division manager overseeing the Perg precast operations. “A lot has happened in the market, and we overhauled the production setup completely to retain our leading position in the industry.” The main aim was to make production more efficient while also improving product quality. Innovative technology options for automating the production process made this step indispensable.

Technological innovation and benefits of the new production line

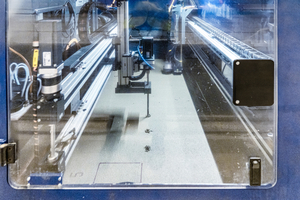

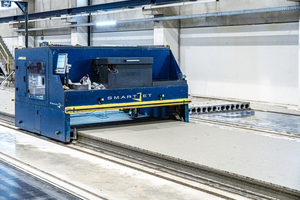

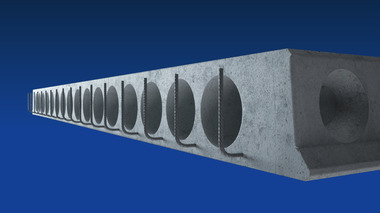

The new production line features numerous engineering innovations that not only increase production speed but also drive down costs significantly. For example, it is now possible to produce up to 40 cm thick hollow-core slabs. The option of manufacturing different slab thicknesses on three 2.4 m wide casting beds adds flexibility for customers. The S-Liner slipformer is the core component of the production line. Its modular design makes it exceedingly easy to produce different element heights within the same product line. Switching to a different product just requires quick changeover of the production-specific module. Thanks to its distinct design and the use of no-slump concrete, the S-Liner is extremely economical and easy to operate and maintain. Another core element of the new line is the automated multi-stressing system, which allows strands to be prestressed in a single pass, ensuring a more uniform distribution of tension while enhancing the slabs’ structural integrity. A multifunctional trolley that places the strands and oils and cleans the casting beds also helps optimize the production process. The automated concrete vacuum unit and the rectangular cutter complement the installed production equipment.

Other important new features include:

CAD-controlled plotter: Data such as cutting angles, project identifiers, and areas to be cut off can be drawn and printed onto the precast elements. Previously, these work steps had to be performed manually.

Automated cutting and drilling equipment: Automating these processes not only reduces labor but also minimizes errors and increases production efficiency.

Less concrete consumed: Thanks to modified slab sections, the new production line saves up to 25% of concrete compared to the previous setup.

These savings are achieved not just on the technical level. “Automating many work steps, such as the new automated drilling unit, also enabled us to drive down costs; and thus prices, significantly,” Karl continues. “Work has also become easier for our people since many manual, physically demanding tasks are now being performed by machines.”

Development options with Progress Group

Collaboration with Progress Group, which had already supplied a mesh welding line to Habau Group several years ago, played a key role in upgrading the production line. Progress Group and its subsidiary, Echo Precast Engineering, were again selected for the new project. “We visited hollow-core production lines in Denmark and Belgium. It was very important for our decision to have a look at similar facilities there,” Karl adds. Visits to benchmark plants, combined with the positive experience and trust in Progress Group, were thus crucial for selecting the most appropriate equipment supplier.

The new production line puts the Perg precast plant in an ideal position to stand its ground amid future challenges for the construction industry. Enhanced production output and added flexibility are crucial for taking the lead in the industrial and commercial construction sectors.

CONTACT

Habau Group

Greiner Straße 63

4320 Perg/Austria

+43 7262 555-0

Progress Group

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979900

info@progress.group