Trends in Steel Mold Manufacturing

Customized stone designs are implemented at the Rampf stone design center. The surface characteristics, interlocking systems, stackability and the natural appearance of the finished concrete block are modeled in 3D simulations and are realized by manufacturing the respective concrete block mold.

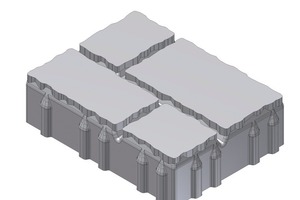

As the fashion industry, manufacturing of concrete blocks is likewise subject to trends. „Finally the customer takes the decision about shape, surface and laying pattern,“ explains Armin Rommel, the chief designer at Rampf. Rampf Formen GmbH is always up to date with its products due to a continuous trend research in cooperation with the customers. „Present trends of stone design move for example towards rustic-style paving blocks with dummy joint, also masonry systems with interlocking and textured surfaces are very popular,“ says André Fuchs of the Rampf stone design center. Rampf Formen places strong emphasis on customer orientation. Thus, any customer has the possibility to realize its own individual block shape and surface together with the Rampf design center. For this purpose, the Rampf stone design center produces virtual 3D models in a faithful scale on the basis of sketches, samples and 2D drawings. „A photo of a surface is all that is needed for a realistic simulation of the surface color and texture,“ states Astrid Sachse. The designers are in the position to develop the ideal block with the aid of 3D technology.

During the simulation the block is already put to the acid test in its design and also concerning its suitability. Rampf Formen guarantees that molds manufactured according to this method will produce an absolutely functional product. Already in the development phase of the concrete block mold it is paid attention to the fact that the block to be manufactured can be produced in the surface characteristics, interlocking system, stackability and laying ability as well as correctly removable from the mold.

With the aid of virtual models it is therefore possible to reduce the production time of the respective customized tool that is to say the concrete block mold. Later production-related changes are avoided in this way and the coordination of development and production is improved altogether.

In addition to this, Rampf offers the production of the respective mold in accordance with the latest technological CSI-Diamond hardening process. The CSI-Diamond has been available on the market for more than three years now and this quality standard has already proved itself under the harsh conditions in day-to-day production operations. These mold inserts have a surface hardness of 68 HRC compared to 62 HRC that is usual in the industry for milled inserts. Even the surface hardness of CSI-Diamond tamper shoes achieve an unbelievable hardness of 64 HRC having an effective hardening depth of 1.2 millimeters compared to the conventional 0.8 millimeters. A quality improvement many furthermore be obtained by the Rampf mold sliding system FlexWay. FlexWay minimizes the wear and tear of concrete block molds many times over. Applying this new system, that can be used together with all Rampf paving block molds, will improve the quality of the manufactured concrete blocks considerably. In addition, the cycle performance will be increased and the reject rate decreased. In this way, costs and expenses will be reduced mold by mold. The visitors of the exhibition GaLaBau taking place in Nuremberg mid September will have the opportunity to see themselves the three-dimensional stone design. Rampf Formen will be present at the German platform for garden and landscape construction as well as sports ground construction with its 3D design stand in hall 4 booth 623.