Acid-resistant, SCC for concrete components in underground construction

We know that concrete has many strengths. We do also know that concrete has a weakness. Its resistance to aggressive media, in particular, biogenic sulfuric acid is just this weakness that is difficult to defy. But as concrete plays an essential role in infrastructure and our sewer system, the topic of sustainability cannot be met with excuses, but only with solutions.

Sustainability is a principle that is actively

followed at the Betonwerk Bieren precast

plant and that is paid particular attention in any product development and process improve-

ment. As a result, self-compacting concrete was

already introduced in the production around 10 years ago, being implemented with the aid of elaborate production control. We were able to

realize high process reliability at a consistent

quality thanks to a stable concrete composition.

At the same time, many municipalities and local authorities already demanded that the issue

of biogenic sulfuric acid in the sewer systems

and its damaging effect on the concrete alled

for solutions. Contrary to the typical concrete

composition trying to improves the resistance according to the principle “some cement, some binder paste, and a lot of resistant coarse aggregates”,

Betonwerk Bieren decided to optimize the self-compacting concrete with regard to the acid

resistance.

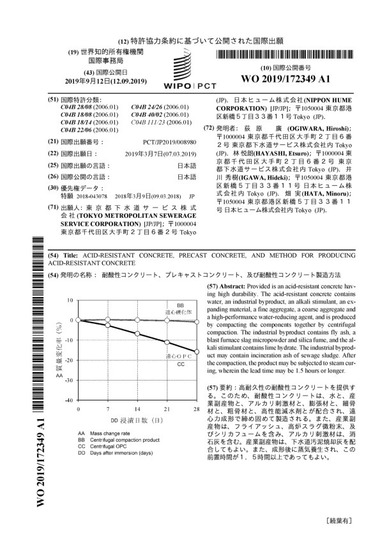

The outcome was an acid resistant, self-compacting concrete (in short: ARSCC)

that was already introduced in 2015 and optimized in 2018. Thanks to the optimizations made in 2018, the resistance and the stability of the mix could be improved

significantly by using aggregates with a maximum grain size of 32 mm. The compulsory examination

according to the “MPA performance test” carried out at Kiwa GmbH based in Berlin was passed without any problems.