Automation of manual tasks in the precast concrete industry

Olthof Groep BV in Sappemeer, the Netherlands, is a family business owned by the Olthof brothers. They have grown into a major player in the production of concrete, precast concrete elements, aggregates, sand and gravel. They are also active in the field of collection of railroad ballast as well as transport and rental of machines and containers. A recent collaboration with Echo Precast Engineering led to the installation of a high-tech automatic plotter SmartJet and concrete aspirator, which allow for faster and more precise work with less manpower.

Livestock farmers become concrete producers

Initially, the company was only active in livestock farming, purchasing a concrete plant to produce the concrete elements for the expansion of their own infrastructure. With the founding of Olthof Prefab they increasingly focused on the production of concrete blocks and prestressed hollow core slabs for third parties. With the construction of a second concrete plant, in 2019 they said goodbye to livestock farming once and for all and concentrated exclusively on concrete.

High-tech solutions

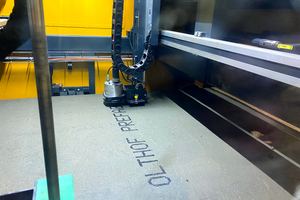

To further optimize their production processes, they contacted Echo Precast Engineering NV from Houthalen-Helchteren in Belgium. They develop, produce and install machines and installations worldwide for the production of pre-stressed concrete elements. A thorough analysis of the specific needs and possibilities led to the installation of an ultra-precise automatic SmartJet plotter for Weep Hole Drilling and a high-performance concrete aspirator.

More precision and certainty

According to the basic data of the architect and constructor Olthof Prefab draws up the laying plan and calculates the floor elements. The new plotter marks the elements and marks cut lines, cut-outs and identification data when they come out of the extruder. Also, weep holes are included in the process automatically. The plotter can mark geometric figures, letters, numbers and even logos on the top and sides, and the plotter can receive the data via USB or WiFi.

Thanks to the plotter, human errors resulting in incorrect cuts or weep holes are eliminated. After all, remanufacturing the wrong hollow core slab is an expensive business, resulting in double fabrication, transportation and crane costs.

The concrete aspirator is placed behind the plotter and, after marking, sucks away the excess concrete at the level of the drains, open channels, openings, hammer heads and column recesses.

The Concrete aspirator also cleans the concrete remains of the track. Through the speed and precision of the work and the saving of a few jobs without significant added value, Olthof Prefab has already increased its efficiency during the production process. Both machines are available in standard and customized versions. All things considered a smart investment that pays for itself quickly.

Roeland Reenaers, Area Sales Manager at Echo Precast Engineering: „What I remember most from this pleasant and smooth cooperation with Olthof is the constructive interaction during the exchange of ideas in order to arrive at an optimal solution“.

Frank Arkema, Works Manager at Olthof Prefab BV puts it as follows: „This excellent collaboration with Echo Precast Engineering enables us to make a great step forward in the scaling up and automation of our production processes“.

CONTACT

Echo Precast Engineering NV

Industrieterrein Centrum Zuid 1533

3530 Houthalen/Belgium

+32 11 600 800