BIM in Thailand’s precast concrete industry

Thai company CPanel Limited is operating one of the first fully integrated precast concrete production facilities in Asia, generating an annual turnover of 11 million US dollars (approx. 9.9 million euros) with a staff of just under 300. The use of Building Information Modeling (BIM) is an important building block in achieving these goals. Tekla Structures, the BIM software developed by Trimble, seamlessly integrates the production systems and other software into the entire value chain. “We have meanwhile become the second-largest precast concrete producer for housing construction throughout Thailand,” says Managing Director Chakrit Theepakornsukkasame. “We are producing precast elements for up to ten houses daily and have lately been able to double our production capacities to 860,000 m² per year.” This makes the company a major player in the building industry and real estate market throughout the region.

The use of state-of-the-art technology such as the Tekla software resulted in an increase in efficiency of 90 % in day-to-day operations and in a reduction of the entire building time by 60 % compared to conventional building methods. Lead times for production of the precast concrete elements could also be reduced from 30 to no more than seven days. The building projects realized by CPanel are, for the most part, located in the Bangkok Metropolitan Region, although the company is present also in other major cities, such as Chonburi. In addition, CPanel is the first producer of precast concrete elements in Thailand to use BIM. Thanks to Trimble’s BIM technology, the design model for the precast elements covers all five dimensions: width, height, depth, time and cost. It is thus possible to not only simulate the building sequence but to also allocate costs to individual elements.

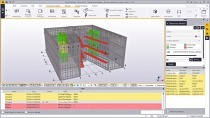

Identifying problems in 3D

The process of switching to BIM began in 2011 when the company served two big customers who not only had a strong cost awareness but were also taking into account marketing aspects and attached great importance to the use of state-of-the-art technologies. These projects were ideally suited to introducing the latest technology, and CPanel began looking for an appropriate software solution.

“We eventually decided in favor of Tekla because it enables us to identify potential problems even before the house has been built. The detailed 3D models helped us shorten development times from ten to a mere two months,” says Managing Director Chakrit. “Our competitors use 3D models as well, but they often need to open a new software for each building stage – for example, one module for walls, one for slabs and another one for the staircases. Using such software solutions is therefore really awkward.”

With Tekla Structures, on the other hand, all relevant information is pooled in a single model. CPanel uses a localized version taking into account Thai design specifications. In addition, Trimble experts from Finland and Singapore provided support to the company during the introduction stage. As part of CPanel’s IT infrastructure, the software is now working with the automated systems governing the plants for the production of reinforcement from AVM and the circulation system from Vollert. In addition, the software offers interfaces enabling manufacturing data to be transferred to the CAM software and data to be exchanged with SAP’s ERP system. It is this flexibility which enables a fully automated integration of the production process.

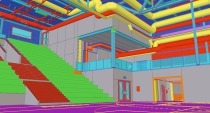

Detailed and complete building models

Instead of CAD data, customers get detailed and complete building models of their projects even prior to the start of construction. Planning procedures and discussions are thus greatly gaining in efficiency. “Some of our competitors are still working on this process manually which, of course, gives us a significant competitive edge. We obtain a finished model instead of a preliminary plan which requires numerous changes to be made.”

The engineers also export the models from Tekla Structures into Trimble Sketchup. Trimble Sketchup is intuitive to use, its purpose being the simple visualization of buildings. It makes it even easier for customers to use the model for planning and communication purposes. CPanel’s client base includes Thailand’s largest construction companies, which offer different building types and modules to their customers and therefore place different demands on their suppliers. “The BIM software helps CPanel to deal with this complexity and multitude of variants,” says Chakrit. “We have the flexibility necessary to cater to the various inquiries and requirements of our customers. Our customers enjoy the added benefit of being able to complete their projects more quickly. Cooperation and the exchange of data are easy and smooth, just so as if we were a single company.”