Big data, networking and maintenance in precast concrete plants

Progress Software Development GmbH is part of the Progress Group and is a company developing software solutions for the precast concrete and reinforcement industries. The powerful product range includes, among others, MES systems for planning, control and optimization of the production process as well as ERP solutions for the complete representation of business processes. A perfect integration of the entire process chain, starting from sales to planning and production through to invoicing, is ensured by the wide range of products. Thanks to experience gained in the industry over decades, the company regards itself as full-service provider and is interested in a long-term cooperation with the customers.

A smooth and perfect workflow in the precast concrete plant is the prerequisite for a company‘s success. This is ensured by a comprehensive information and analysis system that helps to reveal strengths and weaknesses in existing processes in order to support continuous improvements.

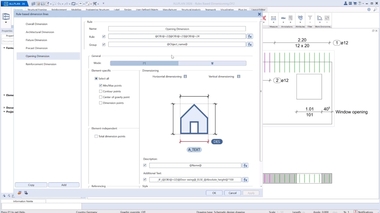

Progress Software Development GmbH has created exactly such a system with Stabos. Stabos is a software system for the collection and analysis of machine and production data. The unique cloud access enables access to data from anywhere. The software already enjoys great popularity both in Central Europe and internationally.

Which modules does Stabos provide?

With the aid of four highly specialized modules, Stabos provides thorough production analysis in the following sections: production statistics (big data), predictive maintenance, KPIs (key performance indicators) and failure analysis:

1. Production statistics: The production module enables a company to determine the productivity and to improve the quality by means of centrally collected data.

2. Predictive maintenance: Stabos significantly simplifies maintenance planning. Maintenance can be planned efficiently thanks to an easy overview on several machines. The system independently produces proposals about when maintenance is to be done.

3. Key performance indicators: The performance of a machine can be easily determined by means of the performance indicators, providing a quick overview on the efficiency of the system. The following key performance indicators (KPIs) can be defined, for example:

4. Failure analysis: Downtimes can be easily recorded with the aid of the extensive failure archive, for reacting to recurring failures in a timely manner.

Satisfied users all over the world

Stabos has been able to gain a lot of satisfied users all over the world since its introduction. This includes medium-sized enterprises from Europe as well as large corporations in Asia.

Thanks to Stabos, many customers have been able to get a better overview and deeper awareness of the daily operations and production processes in the factory and to continue to increase the efficiency of the company as a whole.