Chalice-shaped pillars for the new Stuttgart underground station

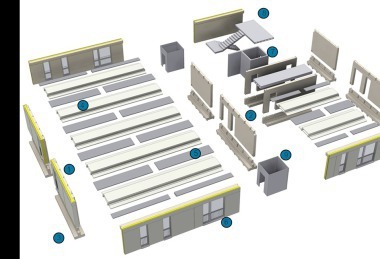

Most of the production processes required for building the unique shell roof in the Stuttgart 21 project were developed from scratch, thus extending building feasibility limits for extremely complex infrastructure projects combined with the highest architectural requirements on reinforced-concrete construction. The formwork is machined to maximum precision at Züblin Timber using CNC robots. The tool paths are derived directly from the model by means of a parametric interface. The reinforcement of each single chalice-shaped pillar comprises approx. 11,000 different rebar shapes, many of them unique items. Approx. 500 rebar shapes require three-dimensional bending, which is highly unusual for reinforcing steel. Installability of the reinforcement and the embedded parts is coordinated in the reinforcement model using the “BIMPLUS” software, which was developed further in collaboration with Allplan. Exceptionally complex relationships were visualized in 3D at the High-Performance Computing Center Stuttgart.

The reinforcement steel is bent, in a bending facility specially set up for this project, mostly via an interface between the reinforcement model and the bending machine. The extremely high requirements on dimensional accuracy are monitored by means of true-to-scale laser projection. Each chalice requires 450 drawings to depict the extremely complex reinforcement design with a steel content of, in some places, up to 550 kg/m³. To assist with the installation, the 3D model is therefore made available via a large screen in the container and as a tablet solution for direct access right on the installation site. Each bar is installed in accordance with surveying specifications on the basis of 3D relief maps from the model at different heights of the reinforcement.

To meet esthetic standards, the concrete used in the project was developed as white concrete in the SB4 exposed concrete class in combination with the specified static properties and the requirements for complying with fire design (addition of PP fibers). The design/as-built check on the completed and demolded shell roof is performed by means of 3D laser scanning and reconciliation with the geometric model.