Changes at white cement producer CRH

White cement is not simply cement with a different color. It is a special building material that allows architectural visions to be realized. Cement producer CRH (Slovensko) a. s. North Danube, which is part of the Irish parent group CRH and will be operating under the brand name Danucem from October, has done a lot to make this even easier in the future.

The manufacturer has expanded its product range from two to eleven different types of cement. This will enable the company to respond even more specifically to the respective requirements in different fields of production and application. It means, for example, that the concrete produced using the white cements will harden more slowly or more quickly in accordance with requirements. It may be more resistant to chemical influences or withstand mechanical attack for longer periods of time.

Architectural advantages

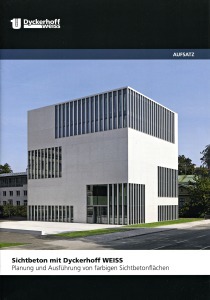

For architects, the new cements offer several advantages, the most important probably being the exceptionally high degree of whiteness that is a distinctive feature of the cement. It even has a slightly bluish hue, giving the concrete a radiant, cool elegance. As an additional feature, the cement can be used to realize sharp-edged, flawless corners and to produce exceptionally thin elements. And the new cements also offer numerous advantages if the concrete is to be colored using pigments: they promote exceptionally brilliant color results.

Smaller carbon footprint – ecologically advanced products

To date, the special binder has been marketed under the name CRH-White but is better known to many customers under the name of its production location: Rohožník. To reflect this and to document the step forward, the producer decided to change the designation of the cement to Rohožník White. This step includes an improvement of the cement’s carbon footprint.

CRH has invested a lot of money into the production facility in recent years, turning it into one of the most modern and environmentally friendly plants in Europe. In addition, the white cements were developed and optimized so as to allow more environmentally friendly raw materials to be used in their production. This development is unique in the white cement sector. With its new range of products, the manufacturer is responding to the stringent requirements for cutting CO2 emissions and making a contribution towards achieving the climate goals. The cements have been registered for CSC certification for sustainable construction.