Energy-efficient cooling and heating solutions for enhancing fresh concrete quality

Solid concrete components are used both in cast-in-place applications and in the precast industry. Such elements can develop a high amount of hydration heat and internal stresses resulting in cracking. This is why the temperature of the concrete needs to be controlled efficiently already during the mixing process in order to prevent severe damage to the building or structure.

Solid concrete components are used for the construction of airports, dams, tunnels, bridges and other infrastructural projects. Owing to their thickness, such elements can develop a high amount of hydration heat and thus internal stresses resulting in cracking even months after their installation. In addition, exceedingly high or low ambient temperature levels can obstruct the controlled curing of concrete in regions with extreme climatic conditions. This is why the temperature of the concrete needs to be controlled efficiently already during the mixing process in order to prevent cracking and, consequently, severe damage to the building or structure.

Thus, construction contractors and concrete producers have to comply with increasingly tight temperature limits imposed by ever-stricter legislation enacted in the past 10 to 15 years as well as with increasingly demanding requirements in terms of the quality and structure of the concrete. At the same time, rising power prices make it necessary to increase the energy efficiency of temperature control systems continuously. One solution to this problem are modular systems that combine the use of ice, water and air in order to meet the demanding concrete temperature requirements while also avoiding energy-intensive cooling and heating methods, resulting in a more favorable energy consumption and carbon footprint.

Temperature-controlled concrete

“Construction is here to stay”, at least according to this famous maxim. Yet sufficiently stable structures will always require huge amounts of concrete, particularly in mega-projects such as Dubai International Airport, which meanwhile extends over an area of 1,400 hectares. In the past, however, insufficient temperature control of the concrete led to subsequent issues with respect to the strength of the installed concrete attributable to poor design and lacking expertise. Hydration-induced cracks that occur owing to temperature differences within the structural component during the hardening process will require subsequent repair and may thus create dangerous weak spots within the load-bearing system, potentially leading to structural failure. The concrete temperature needs to be reduced already during the mixing process, particularly in regions with demanding climatic conditions and extreme temperature levels such as the Middle East, South East Asia and Africa. However, the concrete has to be temperature-controlled (i.e. heated) also in regions exhibiting comparatively cold temperatures and/or greater weather fluctuations because batches kept at an exceedingly low temperature may otherwise freeze and cause structural damage.

In addition, the requirements for handling concrete on-site have become increasingly strict over the last few decades. In many countries, legislators impose exceedingly demanding requirements in terms of concrete strength, resistance and durability, which is also reflected by the specified concrete temperature limits. Furthermore, public and private clients often specify even tighter temperature limits for fresh concrete in order to prevent subsequent quality issues from occurring. In countries on the Arabian Peninsula, for instance, applicable legislation stipulates a temperature of 30°C, but clients often specify a temperature of 25°C or lower depending on the project – despite outdoor temperatures of up to 50°C prevailing in the summer season. Add to this the effect of the frequently used novel high-performance cements, which develop much higher temperatures than standard cement grades during the setting and hardening process.

Concrete cooling using ice – plate ice as an energy-efficient option

Solutions for concrete temperature control can differ widely depending on the climatic conditions and the specific project requirements. One example would be a tunnel project under construction in moderate climatic conditions in Germany, Austria or Switzerland. Applicable legislation requires the concrete to provide a particularly high resistance against seepage water in order to prevent the ingress of moisture and, consequently, damage in the long term. It is thus imperative to prevent hydration-induced cracking.

However, this specification imposes stricter requirements on the temperature of the concrete mix, which must not exceed 20°C during pouring. Despite the moderate climate, this will require the use of an efficient cooling system especially in the summer season. More than 50 tons of ice are needed each day for pre-cooling in order to adhere to this limit while being able to produce a sufficient amount of concrete. Since the client had prioritized the aspect of energy efficiency for this project, an energy-efficient plate-ice plant was preferred over a flake-ice unit. Compared to similar flake-ice systems, plate-ice systems consume about 30 to 45% less energy per ton of ice depending on the ambient conditions.

Aggregate cooling using air as an alternative to ice

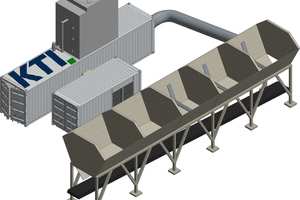

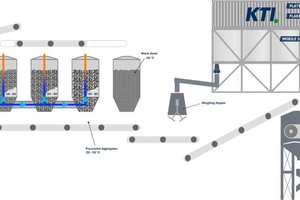

Tropical regions, however, with prevailing temperatures of about 45°C or more pose additional challenges. Accordingly, the second example refers to the production of 1,000 m³ of ready-mixed concrete, which is generally used for the foundations of any type of major building or structure. As in the European project referred to above, the use of plate-ice systems with integrated on-demand cold-water generation could be an option to adhere to the target temperature of 23.5°C specified for the region. However, even the use of more than 78 kg of ice and 36 l of cold water per cubic meter of concrete would result in a fresh concrete temperature of only 28°C, which would be unacceptable because of the water-cement ratio specified to comply with the concrete strength requirements. This is why an aggregate cooling system complements the use of ice and cold water. Prior to the concrete mixing process, this unit cools down the gravel to be added to the concrete mix in sufficiently large silos using cold air blown in through nozzles. The aggregate cooling unit draws in and cleans the ambient air in order to prevent blockages in the heat exchangers, thus ensuring a uniformly high cooling output and reducing the required mechanical maintenance of the system to a minimum. A multi-stage cooling system comprising several heat exchanger packs guides the air to the bottom and then pushes it through the silo, past the gravel, so that the aggregate temperature falls to about 20°C in this project example.

In other cases, the aggregate cooling unit replaces the ice cooling system completely. Combining cooled gravel and cold water is thus much more energy-efficient than ice cooling because the cooling of water and air consumes less energy than the ice production process. In addition, gravel cooling has a significant influence on the mixing temperature, which renders the process very effective because the concrete mix contains about 40 to 60% of gravel. Any 1 K change in the fresh concrete temperature will generally require a corresponding change in the aggregate temperature of about 1.6 K. In contrast, the water added to the mix would have to be cooled down by 3.6 K in order to achieve the same cooling effect.

Dam construction the most demanding challenge

The third and last example discussed in this article refers to dam construction as the type of project posing the biggest challenges in terms of concrete cooling and heating. This scenario is located in a region in the far south of the American continent characterized by low temperatures in winter and relatively high temperatures in summer. Dam projects are invariably associated with complex requirements for temperature-controlled concrete that primarily result from the dimensions of the bulky concrete elements. For instance, from a certain distance between the element core and its surface, heat exchange will virtually cease between the core and its surroundings. Consequently, the hydration-induced buildup of heat and expansion will increase inside the element, with an adverse effect on its structure – either by failing to achieve the specified compressive strength or by triggering more pronounced cracking owing to thermal expansion. This is why care must be taken to ensure, during the mixing process, that a starting temperature of just 10°C is not exceeded. At the same time, cold winter temperatures must not let the temperature of the concrete mix fall below 10°C because, otherwise, voids filled with frozen water would form in the concrete.

In this case, a combination of concrete cooling and heating systems appears to be appropriate under the prevailing climatic conditions. Again, a plate-ice plant is at the core of this setup, providing the advantage, compared to flake-ice systems, of requiring only a single instead of two units for producing the 110 tons of ice needed per day. In addition, the plate-ice plant can ensure the simultaneous supply of cold water, which eliminates the need for a separate cold-water system to deliver the 200 m³ of water required each day to cool the concrete mix. This setup alone lowers energy consumption by about 185 kW while also reducing the amount of refrigerant needed by more than 50%. However, the setup includes a complementary aggregate cooling unit using cold air in order to cool the concrete down to the very low temperature of 10°C, with the added benefit that the same aggregate silos used for cooling in summer can be reused for heating in winter. This setup only requires a cold-air generation unit and an additional unit for generating hot air so that a uniform temperature of the concrete can be ensured throughout the year. As and when required, the respective unit will be connected to the silo, and the hot or cold air will be pushed through the mineral aggregate stored in the silo. In this case, we use three hot-air units as well as a hot-water system for concrete mixing. Since it is difficult to supply green fuels to remote sites, the required heat is generated by combustion of easy-to-store heating oil conforming to EU standards. In contrast, natural gas or biogas is often used in urban areas.

Precast element production as an additional area of application

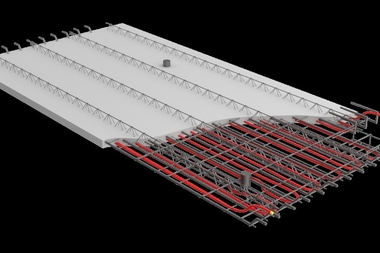

Heating and cooling systems can serve different purposes in precast element production. On the one hand, temperature control of the concrete is still the most important factor. Even though no cracking will occur owing to freezing water in winter or to overly strong solar irradiation in summer, the temperature of the fresh concrete continues to be crucial for determining precast element strength – with the aim of always adhering to the permissible upper and lower thresholds.

Unlike in the case of major projects involving on-site production and delivery, the precast industry requires more compact heating or cooling units because the produced concrete volumes are often significantly smaller, although there are rare exceptions to this rule.

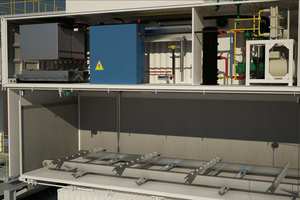

Heating and cooling plants need not always be mobile because precast elements are produced at the factory, but their mobility is often regarded as a “nice to have” feature. Many customers favor containerized solutions, which eliminate the need for a separate room inside the building for accommodating the equipment.KTI-Plersch has installed more than 40 plant setups at precast plants for concrete cooling alone, most of them in hot-temperature countries such as India or the United Arab Emirates. However, such plants are also beneficial in Central Europe. Again, the plant components include cold-water generation as well as ice and aggregate cooling units. In most cases, however, using cold-water units will be sufficient. Aggregate cooling is often used in the case of particularly demanding specifications, including cold air but also, in the precast industry, cold water flooding the aggregate silos. The number of concrete heating systems installed in the field is equally large. On the one hand, heating systems are used for controlling the temperature of the concrete, just like in the cooling process; on the other hand, the secondary utilization of heat comes into play at this stage. Since precast elements are produced in factory buildings, excess heat can be used for heating these buildings. Likewise, such a setup provides the option of also heating the curing chambers in which the precast elements are stored for hardening in order to keep the process stable.

Trend towards compact, energy-efficient systems

In conclusion, the use of cold water and air is superior to ice in terms of energy efficiency, which will become increasingly significant for concrete cooling and heating when looking more closely at currently existing options for saving energy and the global trend towards increasingly efficient industrial plant and equipment.

Another significant trend relates to the footprint required for the concrete cooling and heating plant setup. As demonstrated in the South American example, it is possible to reduce the footprint by eliminating certain plant components, which will definitely pay off on urban or other confined job sites. This is where modular systems are preferable because they can be installed in 20 of 40-foot containers stacked on top of each other, thus reducing the width of the required space. This option is perfectly suitable for reducing the footprint in densely populated areas where space is expensive, while, on the other hand, reducing the costs of transporting the systems to remote sites.