In-house presentation of an ASMS pipe cage welding machine

On 26th March Apilion Machines + Services GmbH in Kehl, southwest Germany, opened its doors for existing and potential customers to come and view a high performance ASMS pipe cage welding machine in operation prior to its dispatch to a US pipe manufacturer.

On 26th March Apilion Machines + Services GmbH in Kehl, southwest Germany, opened its doors for existing and potential customers to come and view a high performance ASMS pipe cage welding machine in operation prior to its dispatch to a US pipe manufacturer.

Managing director Lothar Hartenbauer welcomed numerous guests from Germany and neighboring countries: “Under the name Apilion we are grateful to be able to continue the proud longstanding engineering tradition of our predecessor Züblin MAB, and build on past success in the marketplace. We would obviously love to sell even more machines, but the machines already out there are incredibly reliable and made to last and are always able to find a new home when for whatever reason pipe production plants at which they are in operation cease their activity. Indeed, machines supplied in the seventies and eighties are still in reliable service in South Africa and Argentina respectively.”

ASMS 150 cage welding machine

for Concrete Specialties

The ASMS cage welding machine is being delivered to the Concrete Specialties’ Romeoville pipe production plant situated to the south west of Chicago/Illinois, which until 2009 was previously known as Northwind Concrete Products.

The new machine, which was ordered to satisfy increasing demand for precast concrete pipe in the greater Chicago area, will supplement an identical ASMS which has been in successful operation in at the Concrete Specialties pipe plant in Romeoville since 2008.

Concrete Specialties, with manhole operations north, south, and west and pipe operations southwest and northwest of the city, has a customer base throughout the Chicago area, north into Milwaukee and west into Madison, providing concrete products complying with ASTM specifications. These products are sold to contractors and municipalities for the installation of sanitary and stormwater systems.

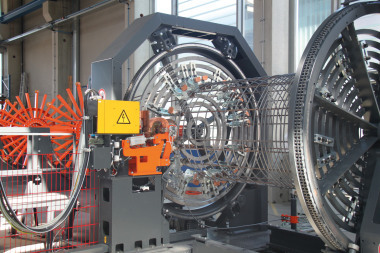

Fully automatic high output cage welding machine

ASMS series high output machines are designed for the fully automatic production off coil of cylindrical resistance spot welded reinforcement cages with spigot and bell socket of any required length. Thanks to the exclusive use of coils for wire feed to the machine, manual loading of longitudinal bars after the completion of every cage which is a feature of conventional cage welding machines is eliminated. ASMS series machines were originally designed by Züblin primarily for use with packerhead and other highly automated concrete pipe production systems, in which large quantities of cage are required.

The longitudinal wires are drawn from the coils at the rear of the machine and fed via guide tubes to the electrodes. As the wires are being advanced the circumferential wire is being continuously fed onto the electrodes and spot welded to them by the rotating welding unit.The reinforcement cage is fabricated in a horizontal position and does not rotate during the production process.

The machine acquired by Concrete Specialties is the very latest version of the tried and tested ASMS and boasting an exciting new development – the synchronization of drive units using state of the art components. These and other machine components are sourced from reputable suppliers such as Siemens for the control system, switches and relays and SEW for motors and inverters and are available worldwide.

A sole operator for the entire cage production process

The employment of commercially available coils facilitates a fully automatic cage production process output, and apart from occasional coil replenishment and cage shearing and removal, the sole operative assigned to the machine has purely supervisory duties. All necessary cage parameters such as circumferential wire pitch, bell angle etc. are also freely programmable.

In terms of numbers the ASMS series welding machinery is designed to produce cages in the diameter range 340 to 3.150 mm with up to 24 longitudinal wires with a diameter of 5 to 9 mm and circumferential wire ranging from 5 to 12 mm.

The automatic longitudinal wire feed off coil and the ability to shear and remove the cage while the machine is in operation facilitates continuous uninterrupted cage production and as a result impressive output figures, which, according to the manufacturer, can be as much as 60 cages per hour which is considerably higher than the output attained by conventional cage welding machinery.

The free 24/7 troubleshooting service provided by Apilion and the well-stocked wear and spare parts depot centrally located in the Midwest offering overnight delivery is especially appreciated by the company’s North American customers.

The ASMS is not disassembled for transportation and as a result installation work requires only 2 to 3 days at the most. The remaining time can be dedicated to machine commissioning and more importantly, to providing operators with exhaustive training.