Lightweight, prestressed carbon-reinforced concrete

floor slabs – New perspectives for the precast industry

Since the 1930s, numerous prestressed thin-walled building elements, prestressed both with and without bond, have been used in construction worldwide. Examples range from buildings with simple slab strips and folded slab structures to complex double-curved structural shell frameworks. The prestressing of steel tendons is today considered to be the state of the art in the construction industry. The prestressing technology using carbon tendons or textiles, especially for thin-walled building elements, has been intensively researched for years but nevertheless continues to raise new questions in order to fully exploit the potential in terms of cost-efficiency, ecology and sustainability. Carbon-reinforced concrete elements with non-tensioned reinforcement are often unable to fully utilize the high tensile strength of the carbon fibers. In addition, external stresses often result in an unacceptably high level of deformation. Due to their very slender cross sections, textile-reinforced concrete elements also have a lower bending stiffness in comparison with conventional concrete elements, which increases their susceptibility to deformation. The prestressing of building elements is a potential approach to solving this problem.

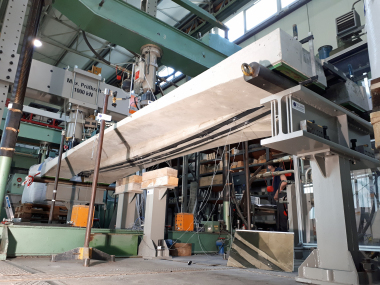

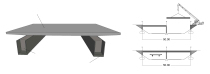

Within the framework of DFG SPP 2187 (Priority Programme 2187 of the German Research Foundation), a next research step aims to ensure that in the precast industry segmented building elements can in the future be manufactured in a flow production process and tested in non-destructive processes to such a degree of precision that their bearing capacity can be accurately predicted and that, as a result, the material coefficients previously used in concrete construction can be reduced significantly and without any loss in safety. The segmented precast elements are subjected to a scanning process using industrial computer tomography, which allows precise statements to be made regarding the concrete quality in areas that will later be exposed to high levels of stress. Similarly, the surfaces can be measured to such a degree of precision that it is possible to accurately predict the

distribution of stresses to be expected in the contact areas of elements joined by prestressing. This not only permits the weight of building

elements to be reduced but also enables them to make a major

resource-efficient contribution to building culture.