Measures to reduce CO2 emissions

More than 6 % of the worldwide carbon dioxide (CO2) emissions caused by humans are associated with the production of cement and concrete. It is a known fact that a purposeful substitution of the burnt cement clinker contained in cement and concrete, respectively, by alternative materials can lead to a significant reduction of the global warming potential. Due to the economic, technological and ecological benefits, in particular, blast-furnace slag and hard-coal fly ash are used as a cement constituent and/or concrete admixture in Germany at present. However, these materials are available to a limited extent, why a significantly increased use of these materials is not possible in the German cement and concrete industry. In particular, widely available limestone and calcined clay represent an additional alternative substitute.

In the last few years, various alternatives to Portland cement clinker to be used in concrete construction, so-called alternative binders, have been investigated and developed such as geopolymer, Celitement and CSA cement, which are not or only partially based on conventional Portland cement clinker. However, their use for common concrete will presumably not be possible in the short and medium term because of pending technical issues (e.g., manufacturing process, durability), normative restrictions or reasons of cost-efficiency.

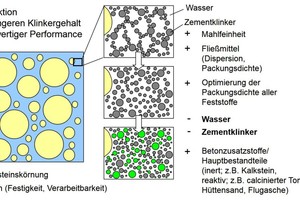

Potential concrete technology measures for reducing the clinker content (Fig.) and replacing the same by environmentally friendly substitutes were already presented by the authors in [1]. A CO2 reduction can be realized immediately by minimizing the clinker content of concrete within the framework of the current normative rules regarding cement and concrete and the national technical approvals, respectively. For the time being, the use of low-clinker cements in accordance with DIN EN 197-1 (CEM II/B and CEM III) is possible for many applications or exposure classes. In addition, the cement content can be reduced up to the respective minimum cement content in compliance with DIN 1045-2. Generally, the addition of inert admixtures, such as limestone powder, or, if necessary, reactive admixtures, such as coal fly ash, is required to ensure the necessary cement paste content. In the short to medium term, a further reduction of clinker or the CO2 emission will only be possible by an amendment of the normative rules regarding cement (DIN EN 197-1) and concrete (EN 206-1/DIN 1045-2).

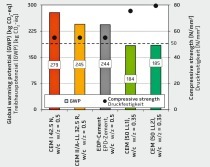

Based on the principle presented in above Figure, the authors developed, with the collaboration of other research partners, environmentally friendly concretes with multi-composite cements made of clinker, blast-furnace slag and limestone. In comparison with the reference concrete made of average German cement (EPD cement), these concretes exhibit significant CO2 savings, depending on the cement composition [2]. A reduction of CO2 emissions of 35 % was achieved for concretes made of cement with 50 wt.-% blast-furnace slag and 20 wt.-% limestone. An application in building practice is foreseeable in the short to medium term on the basis of the draft of the new cement standard (DIN EN 197-1:2014) in conjunction with a national technical approval and/or the inclusion of this cement in DIN 1045-2. The use of the multi-composite cements with 20 % and 35 wt.-% clinker, with a reduction of CO2 emissions of 45 % and 55 %, respectively, will only be possible in the medium to long term by the further development of DIN 197-1 and DIN 1045-2.