New CSC standard for a transparent and sustainable concrete industry

The topic of sustainability is gaining increasing significance in all areas of life. This fact has prompted the concrete industry in recent years to further develop the standards for sustainable concrete production. One of the objectives was to link production more closely with the LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Methodology) classification systems.

In pursuing these objectives, the Concrete Sustainability Council (CSC), an international organization for concrete sustainability, was founded in 2016. The CSC project was launched by the CSI (Cement Sustainability Initiative) of the WBCSD (World Business Council for Sustainable Development).

The CSC is composed of three committees – the Executive, the Technical, and the Communication Committees – which had worked out the certification system and ensure that it satisfies the requirements of the market. These committees are furthermore responsible for continued development of the CSC systems and the associated processes. The company Kiwa Deutschland GmbH is a founding member of CSC as well as a member of the Executive Committee and the Technical Committee.

The CSC has set as its objective the development of an international standard and, in turn, a prominent quality mark to emphasize responsible and sustainable production of concrete products: the CSC label.

Certification criteria

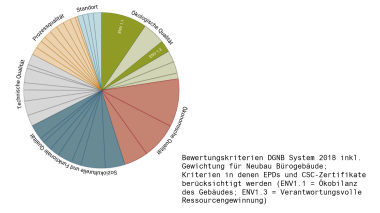

The CSC label is a quality seal, developed jointly with manufacturers; concrete associations from Europe, North, and South America; and third parties such as Kiwa. Classification in bronze, silver, gold, and platinum levels provides transparency and measurable information as to the extent a given product meets the criteria of sustainability. Assessment takes place based on four categories, which are further subdivided into 23 sub-categories. The four main categories on which classification is based are: management processes, economy, ecology, and the impact on the company’s social environment.

The CSC certificate can disclose the extent to which a company in the concrete sector is active in terms of sustainable development. An essential component of the certificate is accordingly an assessment of the impact on the environment and of the effect on the social and economic environment in which the company is active. Differences between the products and/or the company’s production locations, or between several companies, are reflected in the various certification steps of the products and/or the locations.

The CSC system certifies, in addition to the production process, its delivery chain. It is directed to the companies or the organizations in the concrete industry that aim to promote and continuously improve sustainable performance of ready-mixed concrete, precast elements, cement, and aggregates. The objective of certification is to promote responsible production and utilization of resources and to further enhance the transparency of sustainability initiatives in the concrete industry.

Number of assessment points in the CSC Toolbox

In order to assess the delivery chain of the company, the suppliers named in the certification process are requested to perform a self-assessment in the CSC Toolbox. They likewise obtain certification that, however, is based on a different scale than the one applied to the manufacturers. At a score of below of 30 %, they will be given merely the number of points, but no certification. For a score between 30 and 50 % they will be awarded the status “certified”; between 50 and 83 %, the bronze status; and above that, silver. At this time, suppliers cannot achieve the gold and platinum status.

Interested parties may request access to the CSC Toolbox for data on the assessment points awarded to any supplier, once the certification process has been completed. The average number of points of all suppliers will then also be incorporated into the level obtained by the manufacturer.

An annual compliance check, conducted by the auditor of the commissioned certifier, is carried out within the three-year validity period of the certificate.