New measuring system for concrete washout systems developed

The OLAS system from the company Werne & Thiel Sensortechnic was designed for rugged everyday use on concrete and gravel washout systems and is being systematically further developed. The already familiar and commonly used systems for measuring residual water density have flaws, according to the supplier – which Werne & Thiel OLAS has consistently eliminated from the very beginning.

The developed measuring instrument fully meets the requirements placed on a concrete production plant. Accordingly, the present long-term tested and practice-related measuring system – tested over the long term and practice-dedicated – not only promotes environmental thinking but also saves plant operators hard cash.

By now, the OLAS system has been on the market for 12 years and, during this time, the company Werne & Thiel Sensortechnic, by practice-related development directly in concrete production plants has integrated many findings and customer requests in the continuous further development of the OLAS system.

Advantages of OLAS system

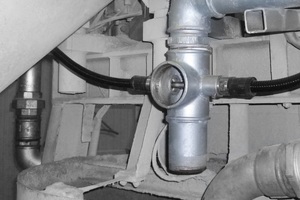

A significant feature of the OLAS system is the measuring head itself, which is in direct contact with the residual water, and which contains no electronic or sensitive parts. The special high-tech electronic system is installed separately in the protective housing near the measuring point. All mechanical parts such as measuring heads and T-pieces can be easily integrated into every system with standardized and readily available components. The measuring results of the OLAS can be directly implemented online in any control system. Many customers of W&T use the measuring results of the OLAS directly in control systems for correcting water and the aggregate values, depending on the formula.

Continuous measuring in a basin or tank or near the intake pipe of the pump as well as measuring in a pipe – e.g., directly during filling of the scales or in a riser. Both measuring options are easily implemented in accordance with the requirements and wishes of the plant operator and can as a rule be carried out directly on site by the plant operator’s own personnel.

The OLAS system offers many advantages: its use significantly contributes to active environmental protection, preservation of resources and thus sustainability. The system, among other benefits, helps eliminate residual concrete in production and supports sustainable handling of fresh water and aggregate.

Active utilization of OLAS in connection with the plant control and the appropriate concrete formulas significantly increases the quality of concrete. The OLAS system offers users considerable savings potential through controlled and adjusted use of recycling water. Among others, smaller residual water containers can be used because, at the end of the production day, through continuous use of the OLAS system, less residual water results. In addition, less residual matter needs to be disposed of, which saves costs and handling time.

The OLAS system can be flexibly integrated and also retrofitted with very little effort in any existing plant and process control system. Installation and maintenance costs are reasonable. Owing to the practice-oriented development of OLAS, there is no electronic system in the wet or dirty areas. Adaption of the T-pieces and measuring heads enables all conceivable installation positions.

Werne & Thiel offers its customers a 5-year guarantee on the complete electronic system of their OLAS systems.

Functioning of optical light fiber and signals

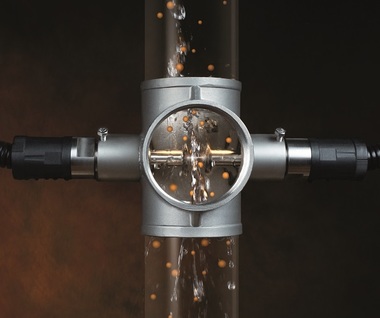

The OLAS system features a strong measuring light source, the light of which is guided into the medium via an optical fiber cable. The measuring light is emitted on the medium-side end of the optical fiber cable (transmitter) with constant intensity, penetrates the medium, reaches in weakened intensity the other end of the optical fiber (receiver) and returns to OLAS via this optical fiber cable.

OLAS measures the receiver intensity with utmost precision and calculates, based on this reading, the absorption of the medium. A receiver intensity of 100% of the transmitter intensity (minimal absorption) results here in an output signal of “0” units. The output signal increases with increasing absorption from “0” units and, at maximum absorption, achieves an output signal of “700” units. The following applies for the analogous outputs: 0V/0mA/4mA = 0 units and 10V/20mA = 700 units. In this way, OLAS can measure receiver intensities of between 100 % and 0.00001 % of the transmitter intensity, corresponding to 7 decades, with every decade containing “100” units.

The measuring heads are connected to the OLAS unit by two optical light fibers. One optical light fiber guide couples the measuring light to the residual water (transmitter) and the second optical light fiber detects the incoming light (receiver). The optical light fibers are available in 5.7 and 10 m lengths and can therefore be adjusted to local conditions. Other lengths are available upon request.

Adjustment of transmitter and receiver

OLAS does not have rigid optical measurement system with a fixed distance between transmitter and receiver; rather, it allows adjustment of the optical distance to the respective medium. OLAS can process receiver intensities in the range between 100 % and 0.00001 % of the transmitter intensity, corresponding to an output signal in the range between 0 and 700. 0 results in a completely transparent medium: i.e., without light absorption. In order to achieve as high resolution as possible in a given application, the distance between transmitter and receiver must be selected such that the entire measuring range from ”0” to ”700” is utilized to the greatest extent possible (minus certain reserves on the range limits).

For application in residual concrete water, a distance has been predefined and a basic setting as well as a calibration curve provided by the manufacturer.

Calibration curve, measuring range and build-up time

The OLAS system always measures the light absorption of a medium. Determination of the composition of the mix therefore always takes place only indirectly, through allocation by the customer of the measured light absorption and the possible matter content. This allocation is also referred to as “calibration curve.” Preparation of such a curve is also referred to as “calibration.”

This calibration curve can be prepared in the control system provided by the customer or in an optionally available display and evaluation unit, the OLAS-TPC unit, by Werne & Thiel. OLAS is able to capture the complete dynamic range from 10,000,000:1 within only one measuring range. This makes OLAS extremely fast and precise: at an instantaneous signal jump of 10,000,000:1 the OLAS builds up the correct measured value in approx. 30 msec. A fast build-up time is a basic requirement when the absorption of rapidly changing media must be measured.

Limits of physical possibilities

OLAS borders on the limits of today’s physical possibilities. In developing the system, an optimal compromise was achieved between a build-up time as fast as possible and an internal noise as low as possible. OLAS itself does not conduct additional averaging, but emits the signal at a maximum rate of change. Excepted from this are the analogous interfaces.

Customers who wish to have additional averaging can include this in their control system or in the optionally available evaluation and display unit. At the OLAS touch panel controller (OLAS-TPC) from Werne & Thiel, the averaging time can be set up over a very broad range.

Some who are familiar with other optical measuring systems may ask whether contaminations or scratches on the optical systems – for example, caused by abrasive media, do not influence the measurement accuracy of OLAS. The fact is that such contamination in practice has very little or no influence at all on measurements. This is because the transilluminated medium, as a rule, is considerably less transparent than is the case with other optical measurement methods, and because it absorbs considerably more measuring light than contaminations or scratches themselves. That means that they do this to a much weaker extent than does the medium. The influence on the measurement accuracy is therefore as a rule negligible.

CONTACT

Werne & Thiel Sensortechnik

Walter Werne & Andreas Thiel

Untere Muehlewiesen 2a

79793 Wutoeschingen/Germany

+49 7756 2425