Non-metal reinforcements for concrete components

The use of non-metallic reinforcements consisting of carbon or glass fiber allows manufacturing thin, slender concrete components, which are durable simultaneously. Since carbon and glass fibers do not corrode, the usual concrete covers can be reduced from several centimeters to a few millimeters. Hence, components with a thickness between 20 and 30 mm are possible, enabling attractive solutions made of concrete, in particular, in façade construction, for balcony parapets, concrete furniture or in the field of rehabilitation.

But non-metallic reinforcements are also predestined for fields not primarily focusing on slender construction but rather have to solve issues of durability as in case of bridges or parking decks, for example. The Albstadt-based company Solidian GmbH has specialized in non-metallic reinforcements and offers along with a wide range of products also technical solutions in the field of carbon-reinforced concrete and textile-reinforced concrete, respectively.

Performance due to high ultimate strength

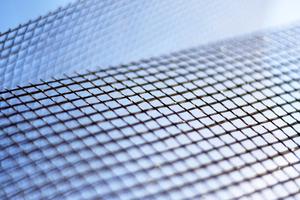

Nowadays, reinforced concrete construction usually solves the issue of corrosion protection by means of a minimum concrete cover, which Eurocode stipulates at approximately 35 to 40 mm for exterior construction components. If the concrete cover is smaller, corrosion damages have to be expected even before the end of the desired service life of the structural components. This results in unscheduled rehabilitation works and high maintenance costs. If, however, non-metallic reinforcements are used, which are usually consist of alkali-resistant glass or carbon fibers, corrosion damages will be prevented. In addition, it is possible to reduce the concrete covers considerably without reducing the durability and the service life; in particular, the use of grid-shaped reinforcements allows realizing concrete covers of only 10 mm depending on the reinforcement cross-section required. The introduction of the composite loads does not cause any problem here either because suitable reinforcement with fiber cross-sectional areas of 0.3 mm² are available (Fig. 1).

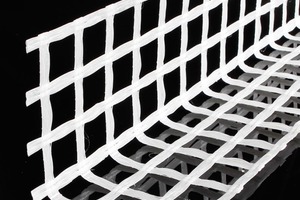

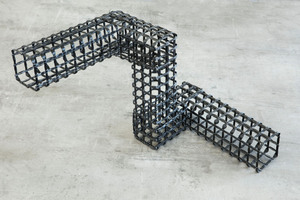

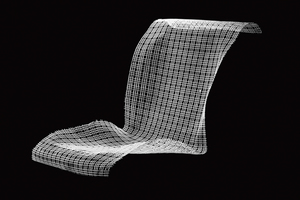

The performance of the glass and carbon-fiber reinforcement, which appears quite filigree in comparison to conventional steel reinforcements is achieved by the very high ultimate strengths. Hence, glass-fiber reinforcements achieve mean strengths of up to about 1,600 N/mm² in the concrete component. Carbon-fiber reinforcements even achieve values of up to about 3,600 N/mm², namely six times higher than steel reinforcement. It is thus possible that today‘s most efficient carbon-fiber reinforcement, Solidian GRID Q142/142-CC38, features about the same structural strength than a Q524 (BSt 500A), which means that it can absorb about 40 tons per linear meter (Fig. 2). Apart from flat reinforcement in mat form or in roll form, the appropriate manufacturing processes also allow producing shaped reinforcement, like L-shaped or U-shaped profiles up to free-form surfaces as well as reinforcement solutions for bar-shaped structures (Fig. 3/4).

Thin, slender and durable concrete construction method

These products are suited to a large variety of applications in concrete construction, namely always if thin, slender and durable concrete construction is required, as in façade construction (curtain wall façades, sandwich façades), bridge construction, parking garage construction as well as for rehabilitation purposes, for example. Recently, an additional bridge made from carbon-reinforced concrete has been completed in Albstadt: On August 8, 2017, building of a bridge took place in Albstadt-Pfeffingen, when a nearly 10 m long road bridge in composite construction was erected within only two hours. The bridge can be passed by trucks weighing of up to 40 tons.

Besides precast construction, there are also solutions from the field of in-situ-concrete construction, for example, the approval Z-31.10-190 of Quinting Zementol GmbH, using carbon-fiber reinforcements in order to reduce crack widths. Carbon-fiber reinforcements demonstrate the enormous performance potential, in particular, in the latter example: using appropriate impregnation materials such as epoxide resin it is not only possible to get a rigid bond with the concrete matrix but also moduli of elasticity of over 210,000 N/mm² can be achieved. In combination with grid openings between approximately 20 and 40 mm, extremely fine crack patterns can be verified which are impermeable to water due to crack widths of maximal 0.1 mm.