Optimization of a hollow core plant

With software, automation, and independent machinery, a production plant can be boosted to be an intelligent plant with many benefits. Echo Precast Engineering want to give some insights into how to boost hollow core plants to make life a little easier for clients in the industry.

With software, automation, and independent machinery, a production plant can be boosted to be an intelligent plant with many benefits. After the challenging year 2020 and a 2021 starting off like the old one, Echo Precast Engineering want to give some insights into how to boost hollow core plants to make life a little easier for clients in the industry.

Why is boosting a hollow core plant a good investment?

In a nutshell: To increase efficiency, safety, and profit as well as save time, raise productivity, and have full control of the production process.

An intelligent production plant is a highly precise and accurate production site with digitized planning, production, and storage processes. These benefits allow for an organized, controlled, and efficient production from start to finish. This is possible through integrating technology of the “Industry 4.0” concept such as the Internet of Things, system integration, connectivity, automation, big data, and cloud computing. To achieve this, clients do not have to start from scratch. If they already have a working plant, they can gradually upgrade technology.

How to boost a hollow core plant?

Adding these solutions to a production process:

Independent battery driven machinery for the

production process;

Automation and

Software automation at its best.

Independent machinery

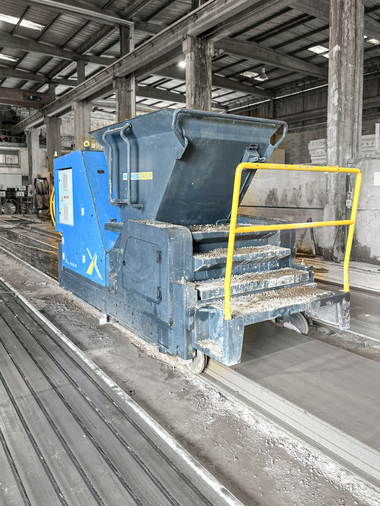

An independent machine is a battery driven machine. Battery driven machines have many benefits with social distancing being the most current, as well as, of course, no cable, which is benefiting their safety, and no fumes, which is healthier. Additionally, the reduction in downtime and staff saves time and money.

Echo Precast Engineering provides the most dynamic battery powered machines, including the Smart Jet automatic plotter, the fresh concrete saw, the multi-functional trolley, and the transfer car.

The special FCS saw for cutting bars into the fresh concrete, for example, also achieves dramatic savings on saw blades because changeover intervals are significantly longer. The machines are more accurate, wireless, and independent.

Multi-functional trolleys allow for the cleaning of production beds, spraying oil (release agent) onto the production beds (release agent) and pulling the strands/wires within approximately 45 minutes.

The transfer car conveys the finished prestressed elements to storage, providing a capacity from 30 to 60 tons.

Automation at its best

Production lines with a higher degree of automation no longer require an operator for each machine. Automation thus saves space and resources while reducing the amount of handling and the number of people on the shop floor. All this comes with a higher output as well as efficiency and with fewer errors.

This of course means that ensuring the successful operation of automated machinery will require teams to learn new skills for managing planning processes and controlling the machines.

The details make the difference. A good example is the Smart Jet plotter, which is equipped with safety and anti-collision sensors for additional safety measurements. The Smart Jet can also plot with regular ink or special UV ink, and its degree of automation helps avoid many mistakes that would otherwise happen during the making of slabs. In addition, the state-of-the-art sawing machines (RAS & MAS) are fully automated. They detect the lines made for the plotter and can run completely independently. These machines, too, include anti-collision sensors ensuring maximum safety for the people working in the plant.

Software as the glue of the intelligent plant

No automation is possible without functioning software. Software connects the machines to each other. For example, it is possible to synchronize the work of the X-Liner extruder, the Smart Jet plotter and the multi-angle saw to work autonomously on a production line.

The “Industry 4.0” concept interlinks all subareas so that consistent transparency is ensured. In the precast concrete industry, this concept also includes bidirectional linking of production machines with production planning and with the BIM model.

Intelligent systems enable smart production that supports employees in the best possible way. They can access the software from anywhere to check and edit data if necessary.

Progress Software Development, a company dedicated to creating software solutions for the precast concrete industry, is also a member of the Progress Group. One of their creations is Ebos, a comprehensive solution for process planning, production, and process analysis. It addresses all aspects of the manufacturing process, from start to finish.

The company also recommends using Stabos, a well-known solution capable of maintaining and connecting all data and information related to the machines, resulting in predictive maintenance and the related outcomes, accessible from anywhere.