Practical solutions in additive manufacturing –

Innovative jointing principles

3D concrete printing as an additive manufacturing method (AM) is a pioneering technology that will significantly accelerate construction process industrialization. The concrete is built up layer by layer, without

formwork, by means of digitally controlled material application, enabling optimized structural elements in terms of material

and force flow. The first 3D-printed pedestrian bridge with a length of 12 m and a width of 1.75 m was built in Madrid (2016),

comprising multiple concrete segments that were previously printed using the particle-bed method. Subsequent projects included an 8-m long pedestrian bridge in Gemert (2017) and a 26-m long pedestrian

bridge in Shanghai (2019), which were assembled from 8 and 44 segments,

respectively, printed using the extrusion method. In the construction of this type of structures, joint design between the printed segments is a

crucial point to ensure undisturbed force transmission. To date, the butt

joints have generally been realized as “wet joints”. In the future, digital

manufacturing will enable the design of innovative, highly precise “dry joints” that will further accelerate construction processes and addi-

tionally facilitate controlled deconstruction. The dry joints can generally

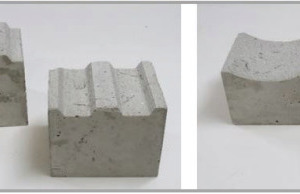

be designed right in the printing process but need to be customized to the 3D printing technology used. CNC-controlled subtractive postprocessing

methods, such as cutting, milling or grinding (Fig. 1a), provide more flexibility, permitting

3D elements of different additive

manufacturing processes to be post-processed at the joints either in a highly customized way or based on a “joint catalogue” (Fig. 1b). The aim is to create

highly precise dry joints with a structural

design optimized in terms of force flow

and the required joint surface properties.

This approach is currently researched

as part of the collaborative research center/

Transregio TRR 277 at TU Braunschweig

by the Division of Concrete Construction

of the Institute of Building Materials,

Concrete Construction and Fire Safety

(Institut für Baustoffe, Massivbau

und Brandschutz; iBMB) and the Institute of Structural Design (Institut für Tragwerksentwurf; ITE).