Production of stairs and ventilation shafts in Russia

The company Irdon operates a precast concrete plant in the city of Shakty in southern Russia to produce all the components for the construction of multi-storey residential buildings with precast concrete parts. The components are produced on tilting tables using different processing machines. Weckenmann Anlagentechnik, the specialist in the production of machines and plants for the precast concrete industry, recently received an order to supply the molds for the production of straight-run stairs and ventilation shafts in two parts for the modernisation and the enlargement of the production plant of the Russian customer Irdon. These molds are used on tilting tables, making use of their heating and vibration system, but also the concrete distribution and helicopter trowelling technology.

Production of stairs on stationary tables

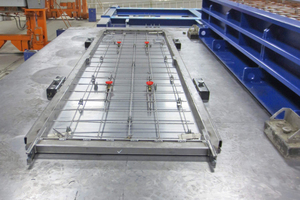

The task was to produce staircases with a fixed width of 1,200 mm and lengths of up to 19 steps. The stairs are produced horizontally and as a negative. The head end of the staircase can be set according to the number of steps required, and magnetically affixed. The side molds are also equipped with magnets and sealed along the bottom rail. Easy and uncomplicated usage of stationary tables or pallets and of the existing processing machines is possible. The staircase length is easy and quick to adjust, the formworks can be easily transported by crane and stacked to save space. The high accuracy of the staircase formworks allow the production of perfect surfaces and sharp edges. The formworks also have a perfect fit and are inexpensive.

Modern production of ventilation shafts:

It is customary in Russia to use ventilation shafts made of precast concrete parts to provide for room ventilation in multi-storey residential buildings. The elements are storey high and, besides the main draught, they usually have two inlet lines opening on each floor in the main draught. These shafts can be produced vertically in multiple molds, where the cores must be pulled within a certain time window. The disadvantage of this method is the relatively poor surface finish and the poor dimensional stability.

The alternative is to produce the shafts in two parts by manufacturing the complex channel part and the cover plate separately. Then the two parts are connected to each other, by welding plates, for example.

A simple solution to this problem is achieved by using a mold which is equipped with foldable side walls, and by producing the cover separately as a flat element.

Both are produced on existing tilting tables, but can also be used on other stationary tables or pallets.

Premium quality

Stairs and ventilation shaft molds, used on tilting tables or in pallet circulation, are an economical solution to produce premium quality standard precast concrete parts for residential building in a flexible manner. Weckenmann manufactures tailor-made and perfectly adjusted staircase formworks and ventilation shafts in accordance with customers` requirements and the needs of the respective market.