State-of-the-art batching plant and concrete distribution system for new Bullivant factory

Piling and foundation elements are the main products at Roger Bullivant Ltd, operating from a Head Office centrally located in South Derbyshire and from seven regional offices across the UK. The reorganization of the precast factories required a new state-of-the-art MCT batching plant and concrete distribution system.

Piling and foundation elements are the main products at Roger Bullivant Ltd, operating from a Head Office centrally located in South Derbyshire and from seven regional offices across the UK. Alongside central office headquarters, the company’s manufacturing facility produces over one million meters of precast concrete piles every year, together with 180,000 linear meters of precast beam.

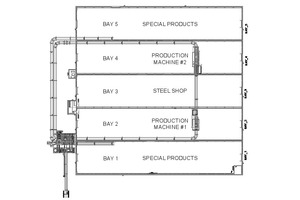

The need of moving the main production facility from Drakelow in 2016 was the reason for the new factory development, which brought to the new site in Walton Park, Swadlincote. Whilst it was ‘new’ site there were further challenges, MCT and other suppliers had to fit their equipment in and around the existing buildings and their features. Fortunately, the five bay building was very well suited for the production requirement and for the materials handling. Its orientation and the surrounding available areas, other than the proximity to residential areas, represented the challenges for the concrete production and distribution systems, since the site layout allowed just a restricted footprint for the batch plant in one side of the building, the furthermost point from the residential side of the site, also to be used for the evacuation of the elements and all site logistics.

A thorough study was required in the supplier selection stage, and the experience and custom design of MCT resulted the best combination for the demanding requirements of this project, along with their efficient and successful solutions for the bespoke plant configuration and distribution system to the production machines.

Mobile plant type MCR ‘on the road’

The reorganization of the factories required an early production of concrete in the new location at Walton Park and MCT proposed the installation of a temporary smart mobile plant type MCR ‘on the road’ to allow the feeding of one bay in the early stage of the final plant design, so to start moving part of the production from Drakelow efficiently and begin the production of elements while designing and manufacturing the fixed plant.

The operators at RB could in this phase get familiar with the performances of the MCT batching systems, which was very helpful also in the commissioning process of the fixed plant, to expedite the training phase of the complete permanent plant and equipment. The plant was developed for the feeding of four bays (1 of the 5 bays is for rebar production with no concrete requirement) in the new factory; the plant therefore had to be installed in a restricted area between two doors on the production bays, to allow the efficient transportation of the elements to the stockyard.

The plant itself comprises of drive-over receiving hopper where the Lorries discharge their materials and these are then taken via a 30 ° chevron belt to the aggregate storage hoppers. The materials are then distributed into the correct compartment through a reversible shuttle belt, and all of these functions are controlled by the MCT Aggregate Feeding system, which runs independently from the main control system. 4No. Aggregate hoppers with a capacity of 40m3 each, 160 m3 in total then receive the materials, and these are monitored via laser probes to ensure the precise volumes are both checked for materials used and materials being properly discharged when filled from the aggregate feeding system.

100 % of water recycled back into the plant

When RB then call for a mix, the materials are collected by MCT’s Mobile Aggregate weigh batcher, capacity of 2 m3, the mobile scale travels under each compartment and receives the correct material volumes, it also allows the materials to be discharged in any order allowing premix of material prior to arriving in the mixer. There were several reasons why this was used over a conventional batching / weigh belt arrangement. Primary reasons were greater accuracy of materials being weighed, lower investment costs, elimination of material spillage & twin mixer plant with skip hoists, using the mobile scale enables the traveling and discharging directly over either of the inclined skips thus removing the need for a traversing weigh belt and the possible problems this gives.

The skip hoists then take the materials to either of the 2 x 2250/1500 planetary mixers, which provide the factory with their 1500 litres per batch of concrete. Upon the mixer platform are the normal components such as Cement Weighing, Water distribution, Admix & dust extraction. Both mixers have two doors allowing either mixer to discharge concrete into ‘outer or inner’ distribution lines that feed the factory. Cement is fed from 2No. 60T (50 m3) silos to either mixing line.The concrete is distributed via one of three travelling buckets, 1-bucket serves bays 1 & 3, the two remaining buckets serve bays 2 & 4, and total distance is 400 m all of which is controlled via MCT’s own control system, providing the optimum delivery around the entire site in automatic mode. The rollover buckets each have a capacity of 2000 litres and can travel at speeds of up to 200 m per minute.

The mixers and travelling buckets are washed via MCT’s own designed washing heads and all the washed water and materials are gathered below the plant where they are separated and 100 % of this water is recycled back into the plant, the waste material can also be recycled.

MCT’s very own Compumat system

All of the dosing, mixing and concrete distribution is controlled via MCT’s very own Compumat system, which is intuitive. As mentioned earlier the fact RB had prior to the main plant being installed already had a good knowledge of this due to the use of the MCR Mobile plant ensured that once production was started on the main plant the training required was significantly reduced.

RB also requested that the plant be enclosed and therefore MCT also provided all of the components allowing the plant to be clad, the structure / design is allows us to integrate the cladding panels to form part of the plant structure thus reducing costs and installation time.

Ian Alcorn, Commercial Director states: “MCT as a supplier demonstrated that they could give RB the complete solution to provide our business with a modern and highly efficient plant, which could be easily integrated to work with our production machines. The fact that MCT’s representative in the UK also supplied our production machines ensured that throughout the project PUK were able to attend our project meetings giving us one point of contact, making this a lot easier for us, another key point was that MCT have ensured that through PUK there is a significant amount of spares stocked in the UK from PUK’s warehouse and offices which are only 1hour from our factory thus ensuring we can have parts supplied anytime of the day if required. Since completing the main project we have also found we have had a need for further additions to be made for extra discharge points along the concrete distribution system and these have been easily and quickly installed, which has demonstrated to us again the flexibility of the MCT plant and ongoing support. We are extremely satisfied with MCT and their partner PUK here in the UK.”

MCT Italy strengthens market competitiveness of UK precast producers

Tony Child, Managing Director of PUK, says: “Being a ‘turnkey project’ all of the matters concerning site organization, erection and lifting equipment had to be well organized by all the parties involved. Roger Bullivant supported us with a very open and collaborative spirit from day one: to ensure projects of any scale but even more so on a project of this size ensuring they run smoothly is paramount and with the relationships formed at a very early stage it was clear that the project would be a success, our ethos is to ensure such relationships are formed from the 1st meetings but it is more about making partnerships with our customers.”

Alessandro DiCesare, International Sales Manager of MCT Italy, points out: “The recent batching plant installed at RB confirms that our approach to listening to our customers’ requirements at the concept and design stages is paramount, this ensures that we find the optimum configurations as every project and site around the world is different. This is our standard custom-based approach and RB saw this from the early stages, which has resulted in a win-win solution. I can definitely affirm that we are proud of the State-of-the-art plant delivered to RB.”

“The consistency and concrete quality exceeded our expectations, and this was apparent within a short period of both plants supplied by MCT starting, we are also extremely pleased with the ongoing support from PUK during project development and since the completion of the main plant. Both the equipment and the service we received then and now are excellent. The high quality and consistency of the concrete we produce with this system is of utmost importance in our production and very easy to achieve. Any problems we did have were immediately and expertly addressed. We would definitely recommend using MCT Italy for future projects”, added David Clement – Production Director of RB.

MCT Italy are represented in the UK & Ireland by PUK Services, a partnership which ensured the best support to the customers with project management during the design and installation phases of this complex project.