The next level

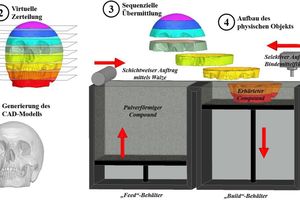

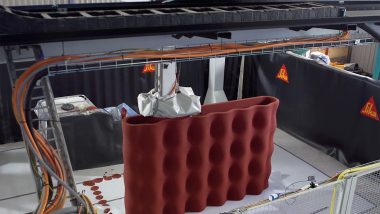

At times, concrete has been regarded as being cold and not very creative. But now this construction material is no longer used only for building massive structures, but is often employed by architects and artists as an eye-catcher for a project. Additive manufacture, particularly with the 3D powder printing process (Fig.), now offers still more far-reaching possibilities of visual design as well as topology optimization of concrete structures to satisfy the personal wish for an individual architectural highlight. In addition, this method can be used for cultural heritage preservation and/or for visualizing new product developments with high level of details of concrete bodies.

Following the successfully completed research project at Kaiserslautern Technical University on “Development of an adapted, cement-bound material for 3D printing of concrete by the powder printing process”, research is now being conducted on further development of this innovative production method. The Department of Building Materials in the Construction Industry at this university, within the scope of an ongoing research project, is currently engaged in developing and implementing a reinforcement system for such 3D-printed structural frames. Successful implementation of this project, in addition to the already achieved characteristic compressive concrete strength typical for the building industry, is intended to lead to a significant increase in the absorbable tensile strength of structural frames subjected to bending. Interaction of the advantages is planned to result in the feasible load-oriented conception of a new structural system.

Investigation into these 3D-printed concrete elements – specifically of subsequently injected reinforcement – takes place by non-destructive computer tomography analysis.

The objective of this innovative manufacture is implementation of structural concrete elements for adaptation to primary load situations and, beyond that, satisfaction of the individual design requests of architects.