Twin-shaft batch mixer used for major project

At present, a Muslim faith community is having the “Mosquée de l’Algérie”, worth approx. 1.1 billion Euros, constructed in the Algerian capital city. The prayer room of the mosque is a huge cube which will accommodate up to 35,000 people. The production of a total of 618 octagonal spun concrete columns used for the monumental building was not a common project even for the manufacturer Europoles from Neumarkt/Germany (for detailed report see BFT 8/2015 p. 44 ff.).

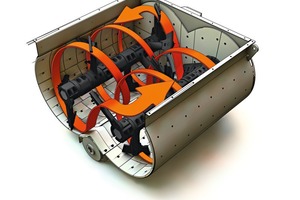

For this large project Europoles needed a new twin-shaft batch mixer of the DKX series of BHS Sonthofen in order to be in the position to produce the required up to 20 m³ of concrete per hour. On the one hand, the mixing times had to be shorter than obtained by the mixers existing in the factory; on the other hand, a separate mixer should be used for the extremely sensitive white concrete, in order to avoid contaminations. Since the share of high-strength concretes and UHPC continues to rise, Europoles, moreover, intended to be well equipped for future projects by this investment in a new mixer.

Compact mixer

with high output

Because of the high requirements on the homogeneity of the mixture, several mixing techniques were excluded within a market research right from the start. Furthermore, the new mixer should be integrated into the existing plant concept without requiring substantial alterations. The plant engineers of Europoles decided in favor of a DKX 1.25 from BHS Sonthofen in order to get a high output at even compact dimensions. Another reason for the decision in favor of this BHS mixer with a nominal output of 1.25 m³ of concrete per batch was the recommendation made by a nearby concrete factory that has been using twin-shaft batch mixers for the production of ultra-high performance concrete (UHPC) for the construction of bridges and wind parks for some time.

As the schedule for the production of the spun concrete columns had already been fixed, the time frame for supply and commissioning of the mixer was extremely short. Europoles awarded BHS Sonthofen with a contract in April 2013, and just six months later, the first concrete mixture was made with the new mixing plant.

Output capacity of up to 16 batches per hour

It is possible to mix up to 16 batches per hour in everyday production, corresponding to an output capacity of roughly 20 m³ of fresh concrete in this period. Up to four columns were manufactured for the mosque project in peak periods, every column with a single weight of up to 30 tons. Experience had shown that the quality of this high-grade concrete mix design is excellent and the requirements on short mixing times are met in peak periods too.

Bernhard Matschiner, responsible for the equipment of the mixing plant, delivers a positive summary, for the time being: “So far, we were only able to manufacture white concrete to a limited extent, as mixing times of planetary mixers would have been too long. The homogeneity of the concrete, which we produce with the mixer of BHS, is outstanding. It is furthermore working reliably and with high availability, so that we are now also in the position to produce high-grade UHPC in large quantities. With the new mixer we have improved our position in the market considerably, in particular with regard to competing materials. In the future, we are going to offer products that will outclass columns made of steel in terms of quality and pricewise.”