Usability of precast construction in seismic regions

Two major Finnish companies offering services to the construction industry, Elematic Oy Ab and Peikko Group Corporation, decided to establish a project that aimed to evaluate the possibilities of using precast technology in seismic areas, with regard to technology and feasibility.

Precast construction can be used in seismic regions. In these areas the design of connections is the key aspect in the construction process. Two major Finnish companies offering services to the construction industry, Elematic Oy Ab and Peikko Group Corporation, decided to establish a project that aimed to evaluate the possibilities of using precast technology in seismic areas, with regard to technology and feasibility. Two specific areas in China with different seismicity levels were chosen for the practical research. The result of this completed project is an example of how a full precast housing system realizes the benefits of precast construction in seismic regions.

Benefits of the precast construction method

Precast construction is an economical industrial-scale method for a range of building and civil engineering projects. The main benefits of the precast building method are a more controlled construction process, faster execution, more effective production – both in terms of manpower and use of raw materials –, and improved quality.

Precast construction is widely used all over the world. There are several different structural systems for different construction segments. The systems vary based on the local requirements, experience and offering of the precast industry in each country. Historically, some European countries, especially the Nordic countries, have been forerunners in the development of industrialized construction.

Today, the biggest construction markets in the world are located mainly in areas where seismic activity must be taken into account in the design. Even in Europe, the number of areas with seismic requirements is increasing. In seismic areas, precast construction has been used to a lesser extent because of a lack of experience, appropriate design methods and instructions. However, precast methods have been used successfully in countries with severe seismic activity, such as New Zealand, Japan, Italy, and the United States. Standards related to seismic design are also evolving rapidly. The experiences of past earthquakes, research, and tests have been adapted quickly into design practice. Each building project must be designed properly based on local conditions, requirements, and codes.

Housing solutions for the Chinese market

Elematic Oy Ab and Peikko Group decided to establish a project to study housing solutions for the Chinese market. The project covered the entire construction process, from urban planning to site work. The main emphasis was on architectural and structural design. In structural design, the main activity pursued related to seismic design and associated structural solutions and connections. The work focused on Chinese markets and requirements but the results could also be used elsewhere. The project was supported by Tekes, the Finnish Funding Agency for Technology and Innovation.

This work aimed to create an industrialized building system for multi-story apartment buildings that also fulfils earthquake requirements. Most of the work was carried out by leading precast expert, Sweco Structures Finland. Earthquake experts from China and New Zealand verified the results.

The work began with a study of existing codes and market requirements for both architectural and structural design. The result was a virtual building that followed the common design principles in China whilst taking advantage of the modern precast technology used in the Nordic countries. The building takes into account the principles of industrialized production and related cost benefits but also allows for a modern, customized architecture. Building physics and thermal insulation have improved significantly compared to existing practice. The aim of the study was to provide answers to the following questions:

Is the building system safe in seismic conditions based on local requirements?

How can detailing and connections be realized?

Are there any references for such systems?

What is the speed of construction?

What are the costs? (In relation to the effectiveness of the layout, the labor required at the factory and on-site, the material consumption of basic materials

What are the facts related to sustainable construction?

Urban planning (i.e. a plan for one block) and architectural design were carried out by one of the leading architectural designers in Finland, JKMM Oy. The main emphasis in this area was on the effective use of land area (floor area ratio; FAR), a specific appearance of the building, and flexible use of the floor area. In this work, several contacts and comments were received from Chinese experts from Tongji University and other organizations.

Urban planning

Urban planning was done for one typical block where the housing block is integrated into a large central park, which provides good opportunities for social interaction (Fig. 1). In Chinese urban planning, the locations (distances) of buildings are strictly regulated and the daylight exposure is controlled by special design rules. However, the effectiveness of the land area used (FAR) is also an important design factor.

Parking is located at street level under the park. Cars and pedestrians are vertically separated, allowing residents to use the park zone above parking. Parking garages are accessed directly from the street.

Architectural design

The architectural design (particularly the floor layouts) strictly followed Chinese regulations and practices but also implemented some aspects of Nordic design. In Chinese practice, the direction and locations of rooms, and locations of windows are strictly specified (Fig. 2). On the other hand, the idea of long spans was implemented because it permits much greater design flexibility inside flats compared to the traditional method, where the spans are typically 4–5 meters.

The basic frame structure is very simple and clear but it also allows for a lot of variation in the appearance of the building with different balconies, textures, colors, and other methods (Fig. 3).

Structural design

The other design tasks (structural, modeling, HVAC, sustainability, cost estimates) were done by Sweco Structures Finland and its sister companies.

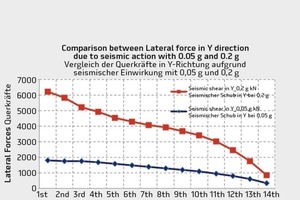

The structural and seismic analysis was completed for two seismic classes (low seismicity, PGA 0.05 g, and medium, PGA 0.20 g). The main design was based on Chinese codes and standards. In cases where there were no Chinese rules available, the design was done according to Eurocodes. In the structural engineering exercise, both calculations and 3D building models were used, and all details and structural drawings for different elements were created through these models.

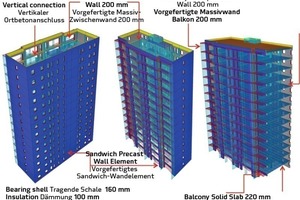

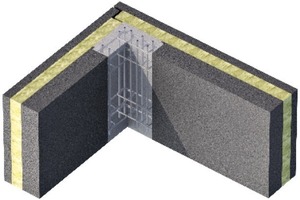

The study building is a multi-story precast reinforced concrete structure located in China. The building has 14 stories above ground level (Fig. 4). The total height of the building is approx. 40 m. The structural system consists of precast load-bearing shear walls in both principal directions. The flooring system consists of pre-stressed precast half slabs (floor planks) with thicknesses of 120 mm and cast-in situ reinforced concrete toppings with thicknesses of 100 mm.

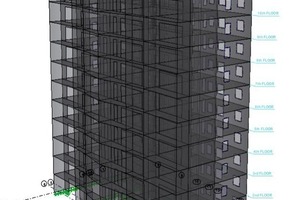

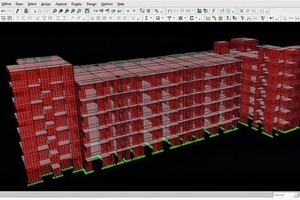

Structural analysis was carried out using the 3D finite-element method (Fig. 5). The lateral resisting system of the building consists of precast concrete shear walls that can brace the structure in both principal directions. The floor consists of precast half slab elements and cast-in situ concrete slabs. The floor was modeled so that the slab acts as a rigid diaphragm to transfer lateral loads. The seismic action is represented by the elastic response spectrum according to EN 1998-1 in selected soil conditions. Later, in the inspection phase, experts from China and New Zealand verified the seismic actions. The verification confirmed the calculations.

The seismic actions were compared with two Peak Ground Accelerations (PGA 0.05 g and 0.2 g) and, as expected, the actions are significantly higher with higher PGAs (Fig. 6).

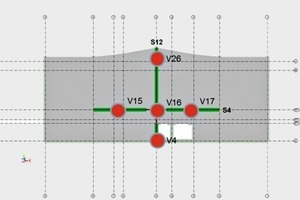

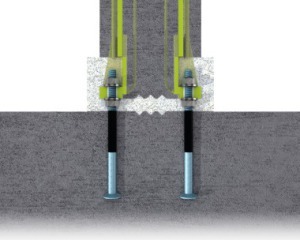

Structural design in seismic areas is much more demanding than ordinary design in non-seismic areas. In the case study, all of the required phases, including structural regularity, the modal response spectrum, and displacements, were analyzed fully. A total of 29 different load cases were analyzed. The key result of these calculations is the critical loading in the connections (Fig. 7). The design of the connections is the most important aspect of precast design in earthquake areas. The connections must fulfil all loading requirements whilst being ductile enough to withstand all deformations.

The designed connections combine Chinese design practice with experience from the Nordic countries. In the Chinese standards, connections are specified in considerable detail. They often follow the principles used in cast-in-situ structures and are quite complex. However, these principles can also be used in precast construction (Fig. 8). The entire building was modeled using the Tekla Structures software (Fig. 9), and the production drawings were generated with this software. The software also created the bills of quantities.

Resource-efficient construction

The proposed building system fulfills the strict require The proposed building system fulfils the strict requirements of the Green Building Evaluation Standard. The flexible and adaptable building concept can be implemented in all of the climate zones in China. The concept can be modified from a simple housing solution for small towns to a high-tech living environment in a modern city.

Resource-efficient construction refers to minimizing material use in construction, using locally produced materials, long product life cycles, easy maintenance, and recycling of materials and components at the end of the life cycle of a building. Long service lives and highly durable materials are essential characteristics for resource-efficient construction. These characteristics reduce the need for new materials and the need for renovation. At the same time, resource-efficient construction requires anticipation of future demands for buildings to make sure that they remain affordable and usable for future needs.

The suggested precast concrete building system is an energy-efficient construction method. The energy saving level can vary, according to the design preferences and the specific case, from 50% to 80% in residential buildings compared to the average level in 1980. Good thermal insulation is easy to include in the design and to install in a factory environment.

Economy of building systems

The economy of any building system must be calculated for the entire lifetime of the building. This means that energy consumption is one of the main factors. The other important part is the adaptability of the system during use. In this respect, the use of long spans with minimal numbers of heavy load-bearing walls is the key factor. The interior of the apartment can be modified easily when user needs change.

The economy of the developed building system is based on the effective production method both at the factory and on the building site. Total construction time can be reduced significantly compared to the conventional method. Moreover, the number of workers required on-site is smaller. In a factory environment, it is also easier to maintain a high product quality standard, and the exposed product surfaces require less finishing work. The other factor of economy relates to the effective use of raw materials. In this case, the total amount of steel is 30% lower than in conventional cast-in-situ construction, with 20% less concrete used. This is achieved by using long spans and prestressed floor components, which also result in fewer load-bearing partition walls.

From virtual project to practice

Elematic and Peikko have continued their efforts to implement precast technology in seismic markets. In many cases, the biggest problem to be overcome is the strong building tradition and related design practices. Very often, it is quite difficult to benefit from the main arguments in favor of precast (long spans, fast and safe site work). The best way to convince the market is to implement actual projects. Elematic has been successful in India where the earthquake conditions are close to those in China (Fig. 10). During the last few years, many factories have been sold and significant building projects are ongoing.

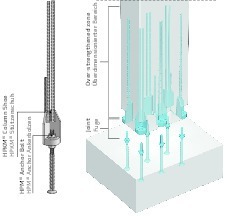

As a steel connection supplier for concrete structures, Peikko Group has continued its work on the topics of the study. In addition to Peikko’s global product testing activities, Peikko’s precast connections have been tested by local Chinese experts and universities according to local specifications (Fig. 11).

Conclusion

The use of precast construction in seismic areas is increasing. The positive experience and evolving design standards in countries such as New Zealand, Italy, Japan, and the United States lead to an increase in confidence. The research work completed in these countries has been significant. It is obvious that the design of precast buildings is more demanding in seismic areas than in non-seismic cases. However, analysis tools have been improved significantly, which is why actions and deformations can now be calculated more quickly and easily.

The study completed by Elematic and Peikko clearly shows that it is possible to use precast technology in residential buildings in seismic areas. It is possible to achieve remarkable savings in the use of steel and concrete whilst shortening total construction time. In this way, a significant proportion of the work can be shifted to industrial manufacturing, thereby increasing the safety and efficiency of the entire building process.

However, the design of connections is the key aspect in seismic areas. All connections must provide sufficient capacity and ductility to serve a wide variety of situations throughout the lifetime of the building. With good design, seismic requirements can be fulfilled.