Waterproof extension totally impermeable

When connecting new waterproof concrete components to existing structures, movements resulting from concrete shrinkage or subsidence, for example, have to be absorbed in the joint. The respective local conditions always differ considerably in this regard. Common joint sealing systems are not suited for the waterproofing design of building connections. It is either not possible to integrate them in the component of the existing structure or, due to a lack of flexibility, they are not able to absorb occurring deformations. The Kunex clamp joint system of H-Bau Technik that is certified by national building authority ensures the connection of joints between old and new structures without any problems.

Being approved by a national building authority test certificate (abP - allgemeines bauaufsichtliches Prüfzeugnis), the Kunex clamp joint provides all parties involved with planning security and design reliability. The verification of applicability meets the requirements of the DAfStb Code of Practice on Waterproof Concrete Structures (WP Code of Practice). The scope of application officially tested and stipulated in the test certificate (abP) applies to soil moisture, non-pressurized and pressurized water up to 5 bar as well as areas of fluctuating water levels. The Kunex clamp joint meets the requirements of service class A for stress class 1 and 2 in accordance with the WP Code of Practice. The system enables the design of waterproof expansion joints for building connections with a width of up to 30 mm and a resulting deformation (vr) of maximum 20 mm.

Waterproofing according to the principle of a labyrinth

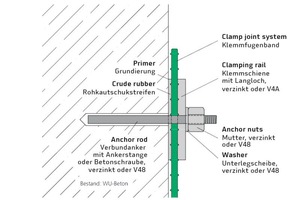

The system includes a primer against absorbent substrates, joint tapes in accordance with test certificate P-5143/478/13 of Braunschweig Materials Testing Institute for the construction industry or DIN 18541-2, steel profiles (stainless steel or galvanized), the injection system with anchor rods or bonded anchor bolts and a crude rubber strip. A clamp is used to press the joint tape onto the existing building structure, where it is additionally embedded in the newly concreted components and waterproofing takes place according to the principle of a labyrinth (extending the water circulation path by means of many changes in direction).

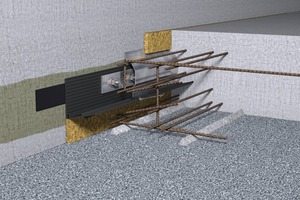

An assessment of the condition of the existing surface and its professional preparation is essential for the quality of the clamp joint. Afterwards, the holes for the erection of the anchor rods or bonded anchor bolts are drilled in the existing structure. After attaching the crude rubber, joint tape, clamping rail and washer to the anchors, the construction is clamped to the building structure by means of anchor nuts. The sealing effect is achieved by pressing all-over the concrete surface. The nuts are tightened to the required torque of 80 Nn and are tightened again after 90 minutes at the earliest.

Reference project Bonn Marriott World Conference Hotel

The Kunex clamp joint has successfully been used at Bonn Marriott World Conference Hotel which was opened in June 2016. The building is part of the adjacent World Conference Center Bonn (WCCB). Situated in the former government district and on the banks of river Rhine, the hotel is perfectly located for meetings, conferences, events as well as holiday stays, providing rooms and facilities accordingly.

The cornerstone ceremony took place in May 2007. The design came from the architectural office Yes Architecture based in Munich and New York. The project was stopped after the insolvency of the Korean investor in 2009, until the city of Bonn took over responsibility and became builder for the conference part and sold the shell construction of the hotel to Bonn DevelopVisio Projektentwicklung und Generalübernehmer GmbH in 2014. In autumn 2014, the hotel tower with the connection building to the conference center as well as the logistics building were completed. The contract was awarded the Bonn-based Hans Blatzheim Bauunternehmung GmbH & Co. KG and the Architektur- und Ingenieurbüro GPG based in Cologne.

The Kunex clamp joint provides for the water-impermeable connection of the underground logistics building of the existing high-rise building. The client was convinced by the national building authority test certificate of the system solution. Approximately 130 m of clamp joint tape were used together with the accessories of the same length (clamping rail, crude rubber strip and protective profile), suitable connection anchors and anchor rods as well as joint tape clips.