Worldwide innovation in connection technology

The Finnish manufacturer Peikko brings to the market the world innovation Tenloc. The greatest advantage of Tenloc is the instant form-fitting and friction locking connection of individual precast elements to each other. Structural and loadbearing connections are established within seconds.

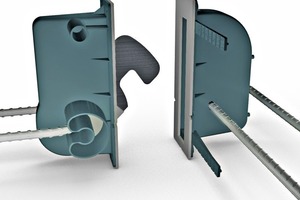

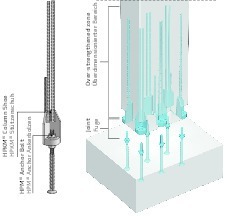

The system is a combination of a latch system and an anchorage system – the latch system is cast into one precast element and the anchorage system into another precast element adjacent to the first precast element; the latch system of the one component assembly then, during assemblage, engages with the anchorage system of the opposite component assembly to establish a connection with the reinforcement of the other precast element. The principle of the Peikko innovation is applicable both for connecting abutting walls and for corner and T connections.

Simple installation

The two-part Tenloc element connector is housed in a box specifically developed for that purpose. The latch system can be turned by the fitter with a hexagonal spanner through the opening in the box so that the latch encloses the reinforcing bar on the opposite side. The fitter initiates the actual tensioning process by continuing to turn the spanner after locking, thus establishing a flush connection.

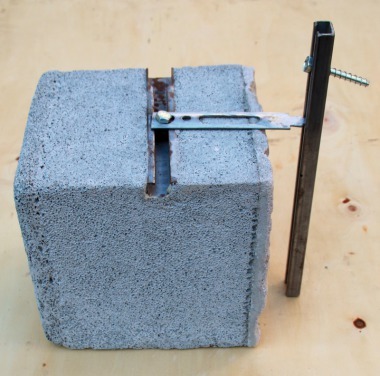

In the precast plant, the two parts of the element connector are positioned on the form tables prior to casting. Special markings and spacing strips on the boxes containing the latch and anchorage system facilitate exact positioning.

Within the scope of the comprehensive tests carried out with Tenloc, Peikko cooperated, among others, with Xebex, a leading supplier of precast elements for building construction headquartered in the German city of Bad Dürkheim. One of the first successful pilot projects to be completed was an oversized precast garage, fitted with Tenloc element connectors.

Peikko has the production facilities of the Tenloc element connectors regularly tested and certified by independent institutions.