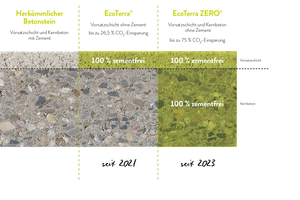

Cement-free concrete block “EcoTerra ZERO” of the future

Metten Stein+Design has successfully taken a big step towards more sustainability. After many years of research and development work, the family-owned company based in Overath presents a concrete block with „EcoTerra ZERO“ that is 100% free of cement. This allows them to save up to 75 % of carbon emissions in the production of the blocks. At the same time, several properties were improved: no lime efflorescence, better color fastness, easier to clean and completely recyclable. The concrete blocks can be used in the private area (garden and terrace) as well as in public space (squares, boulevards or pedestrian malls).

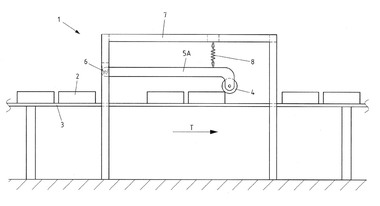

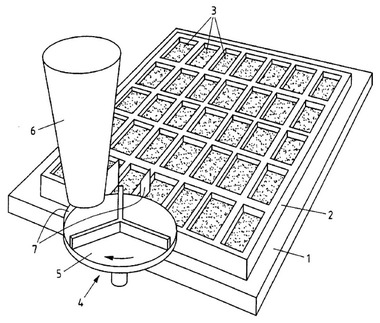

In the production of the climate-friendly block merely gravel, quartz, sand, and water are used – but no cement. Due to the special production technology, up to 75 % less carbon is emitted per square meter at a block thickness of 8 cm – with remaining the same load-bearing capacity and service life and with being visually identical to conventional concrete blocks. The EcoTerra technology allows for the production of blocks in different shapes and thicknesses of 30 x 15 cm up to a size of 100 x 100 cm, for example. Different surface finishes and color shades are also possible.

Variable use in high quality

Moreover, the cement-free concrete block convinces by a large number of improved product properties. Due to the fact that cement is eliminated, lime efflorescence does no longer occur. Consequently, the colors remain more intense permanently. The block surfaces absorb less dirt, thus being easier to clean. Another aspect of sustainability: Recycled material is used for the base mix concrete. All Metten concrete blocks are a 100% recyclable and can be returned to the production process for new blocks in a circulation system. Complemented by the Aqua system, the paved areas are also permeable to water.

CONTACT

Metten Stein+Design

GmbH & Co. KG

Hammermühle

51491 Overath

+2206 603-0