Circular economy for concrete pipes: new pipes made of old pipes

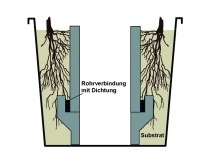

Sewer systems are one of the most important elements of our built environment. It is the backbone of our health and critically contributes to the performance capacity of society. The mega-trends of urbanization and environmental protection lead here to major challenges. The sewer systems must be durable in order to reliably fulfill their function. In addition, the construction materials used must be recyclable to enable possible adjustments to population growth in a resource-saving manner.

Concrete pipes and reinforced-concrete pipes are made of mineral construction materials and can be completely reused as recycled aggregate. The objective of achieving maximum possible use of recycled concrete rubble in pipe production, however, has until now been in part limited by normative requirements, and – for technological reasons – by high and fluctuating water absorption levels as well as by the large and rough surfaces of concrete rubble. Both negatively affect the production and quality of concrete pipes made by the immediately demolded production method.

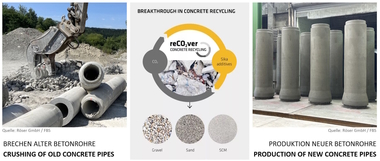

With the reCO2ver method, Sika has developed a processing technology that results in virtually pristine sand and gravel quality of recycled aggregate.

Within the scope of a pilot project carried out with the German Bundesfachverband Betonkanalsysteme e.V. (FBS) and the Röser Corporate Group, old and precrushed concrete pipes were treated with the reCO2ver method from Sika in the pilot plant in Weiach (Switzerland), and new pipes were produced with the recovered materials at the Röser II location in Krauchenwies (Germany). The individual steps from preparation of the concrete rubble by the reCO2ver method – from preliminary laboratory tests to industrial test production – led to important insights that can critically revolutionize the circular economy of concrete.