Lightweight granular materials made from mixed masonry rubble for use in infra-lightweight concrete

Using lightweight granular materials in infra-lightweight concrete appears to be promising for reducing its environmental footprint and thus enabling energy-efficient and sustainable construction. This article reports on lightweight granules, their use in infra-lightweight concrete, and related tests in comparison to conventional expanded clay.

Introduction

Infra-lightweight concrete exhibits an extremely low dry bulk density of up to 800 kg/m³ while also providing sufficient strength, resulting in low thermal and acoustic conductivity. This allows it to be used as exposed concrete in wall panels without requiring an additional insulating layer [1].

Using lightweight granular materials in infra-lightweight concrete appears to be promising for reducing its environmental footprint and thus enabling energy-efficient and sustainable construction. Lightweight granules are produced from mixed masonry rubble in a thermo-chemical process. In addition to being an alternative to conventional lightweight aggregates, their use also provides the opportunity to put waste products to good use. This article reports on lightweight granules, their use in infra-lightweight concrete, and related tests in comparison to conventional expanded clay.

Background

Infra-lightweight concrete (ILC) is a densely structured lightweight concrete exhibiting an exceedingly low bulk density between 600 kg/m³ and 800 kg/m³. Its compressive strength ranges from 5 MPa to 18 MPa [2]. The term was first introduced in 2006 by the Department of Conceptual and Structural Design at Technische Universität Berlin [3]. The literature also uses “ultra-lightweight concrete” as a synonym. In addition to TU Berlin, in-depth research into ultra-lightweight concretes was conducted at TU Kaiserslautern (today University of Kaiserslautern-Landau), University of the Bundeswehr Munich, and at Eindhoven University of Technology [4, 5]. Practical use of this new type of lightweight concrete, for example for monolithic wall panels, has already been demonstrated in various projects in Germany and Switzerland, including the construction of several detached houses and a grocery store [4, 6, 7].

Using lightweight aggregates is an essential prerequisite for achieving the low bulk density of infra-lightweight concrete. Expanded glass produced by recycling waste glass is frequently used for this purpose [4, 8-14]. Other options include expanded clay [6, 15], expanded polystyrene [16], and expanded perlite [17-19].

A promising alternative is the use of lightweight granules produced from mixed masonry rubble in a thermo-chemical process. Options for recycling and reusing mixed masonry rubble are currently limited, which is why it is mainly used for backfilling or profiling landfills. Among other reasons, this is due to the heterogeneous composition of the material from different types of masonry, such as concrete, brick, aerated concrete, sand-lime bricks, natural stone, or gypsum and mortar, which results in diverse physical, chemical, and mechanical characteristics. Masonry rubble contains a substantial proportion of fines smaller than 2 mm. It may also contain impurities such as sulfate. These characteristics rule out its reuse as recycled aggregate in concrete.

The production of lightweight granular materials from masonry rubble relies on research into process development conducted since the early 2000s [20]. Headed by Prof. Anette Müller, this process was further developed to pilot scale at the Weimar Institute of Applied Construction Research (IAB Weimar) [21, 22-25]. It involves a multi-stage mechanical process including the work steps of crushing, grinding, adding an expanding agent (usually silicon carbide powder), homogenization, and wet granulation. The green granules initially produced from the masonry rubble are treated in a rotary kiln at a temperature of about 1,150 °C [25]. At this temperature, the feed material reaches a pyroplastic state. The simultaneous release of gas due to the decomposition of the expanding agent causes the granules to increase in volume and become porous. In addition, sulfates contained in the raw material are decomposed. The resulting sulfur dioxide can be separated as gypsum in a flue gas scrubber. The characteristics of the lightweight granules closely resemble those of expanded clay. This is why similar fields of application are possible, including lightweight aggregates for concrete [23, 26].

Characteristics of lightweight granules and production of infra-lightweight concrete

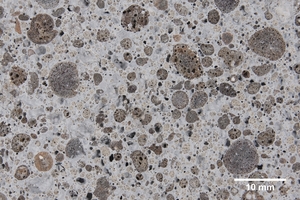

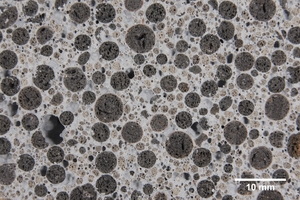

Lightweight granules with a particle size of 2-4 mm and 4-8 mm produced at the IAB Weimar pilot facility were used for the infra-lightweight concrete (Fig. 1). Table 1 provides an overview of the characteristics of the lightweight granules. Their low particle bulk density makes it possible to classify them as lightweight aggregates in accordance with DIN EN 13055:2016. A concrete mix design adapted to the lightweight granules was developed based on Celitement, a hydraulic binder. Commercially available expanded glass was used for the fines proportion. Lightweight granules were used for the coarse fractions accounting for 65% by volume of the total aggregate volume in the concrete. The lightweight granules were pre-wetted prior to concrete production. The w/c ratio of the mix was 0.46.

In addition, a reference concrete mix was produced in which the lightweight aggregates were replaced by commercially available expanded clays in equal proportions by volume. Table 2 lists the constituents of both concrete mixes. The expanded clays used exhibit approximately the same properties as the lightweight granules in terms of bulk density, total porosity, water absorption, and particle strength (Table 1).

Characteristics of concrete mixes

The properties of the fresh concrete produced with lightweight granules (LG-800) are similar to those of the reference mix containing expanded clay (BT-800) (see Table 3). Owing to their high slump, both mixes are very flowable and can be assigned to class F6. Fresh concrete bulk densities amount to 929 kg/m3 and 960 kg/m3, respectively, while their air content is 22.5 % and 19.5 %, respectively.

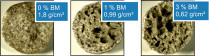

Fig. 2 shows the cut surfaces of the two concretes clearly showing the porous structure of the lightweight aggregates and the large number of air voids in the concrete. In addition, the lightweight aggregates show a somewhat more irregular shape compared to the expanded clay, which is confirmed by the sphericity values determined using dynamic image analysis (Camsizer, Retsch) (Table 1). The closer the value is to one, the higher the sphericity. Table 4 provides an overview of the hardened concrete characteristics for both mixes. The LG-800 mix can still be classified as an infra-lightweight concrete due to its dry bulk density of 800 kg/m³. The reference mix has a slightly higher density. The high porosity of over 60 % determined for both mixes is attributable to the considerable proportion of air voids contained in the concrete matrix as well as to the macro and coarse pores in the lightweight granules [26].

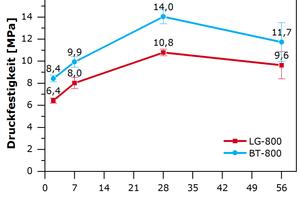

Concrete compressive strength was measured on cubes with an edge length of 150 mm. After production, the specimens were stored in accordance with DIN EN 12390-2:2019: They were first covered with plastic film for 24 hours, immersed in water until a specimen age of seven days, and finally stored at 65 % RH and 20 °C. Tests were conducted at an age of 2 to 56 days (Fig. 3). Mix LG-800 reached its maximum compressive strength of 10.8 MPa after 28 days. Both initial strength and 28-day strength were slightly higher for the BT-800 reference mix. Both concretes can be assigned to compressive strength class ILC7 [27].

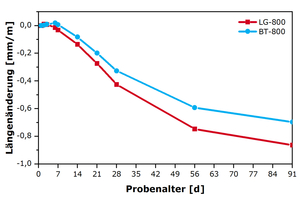

The shrinkage and expansion behavior of the concretes was tested on prisms measuring 40 mm × 40 mm × 160 mm. After production, the prisms were covered with foil for 24 hours and then stored at 60 % RH and 21 °C. Minor concrete expansion was found in the first few days after production (Fig. 4). This presumably results from the release of the water stored in the aggregates to the cement paste. Drying shrinkage occurred from a specimen age of about seven days. After four weeks, concrete shrinkage decreased continuously. At 28 days, the change in length equaled -0.43 mm/m for LG-800 and -0.33 mm/m for BT-800. Extent and progression of shrinkage are similar to the infra-lightweight concrete described in the literature [6].

Thermal conductivity values were determined using a Hot Disk measuring instrument at 10 °C on specimens measuring 100 mm × 100 mm × 30 mm. Both the LG-800 mix and the reference achieved an average thermal conductivity of 0.25 W/mK. As expected, measured thermal conductivity values were significantly lower than the range of 1.5-2.3 W/mK specified for standard concrete [28]. The results thus confirm the effective thermal insulation provided by infra-lightweight concrete containing lightweight granules aggregate.

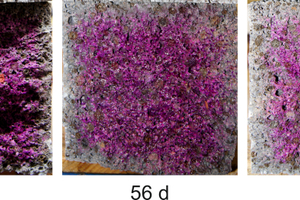

Freeze-thaw resistance was determined in slab tests performed on five 150 mm × 150 mm × 50 mm specimens that had previously been sawn from cubes with an edge length of 150 mm. Prior to the first freeze-thaw cycle, sawn specimens were first stored at 20 °C and 65 % RH and then immersed in water for three days. Deionized water was used as the test liquid. Freeze-thaw cycles between 20 °C and -20 °C lasted 24 hours. The mass of the material scaled during any cycle decreased with the increasing number of freeze-thaw cycles. After 56 cycles, surface scaling of the infra-lightweight concrete LG-800 totaled 86.4 g/m2 while it amounted to 45.2 g/m² for the reference. The assessment criterion of 1,000 g/m2 after 56 cycles for normal concrete was converted according to Faust using the bulk density of the ILC LG-800 mix, resulting in a permissible scaling of 381 g/m2 [29, 30]. Actual values were significantly lower than this limit, which proved the high freeze-thaw resistance of both infra-lightweight concrete mixes.

Progression of carbonation was investigated for a natural carbon dioxide content at 20 °C and 65 % RH. The carbonation front on the specimens’ fracture surfaces was made visible using a phenolphthalein indicator solution, and carbonation depth was measured (Fig. 5). A constant k describing the carbonation rate can be estimated from the carbonation depth x at the measurement time t applying the square-root rule [31]:

Both concrete mixes exhibit a high carbonation rate due to their high porosity. For LG-800 and BT-800, k is slightly higher than 20 mm/a0,5, which is consistent with the ILC values found in the literature [2]. Based on these measured values, a carbonation depth of 20 mm would be reached after less than one year. This corresponds to the depth at which the reinforcement is usually located in concrete. Consequently, there would be a high risk of corrosion for the reinforcing steel. This is why alternatives such as galvanized reinforcement or glass or carbon fibers must be used in ILC mixes. It is also possible to design thick, non-reinforced components.

Summary

An infra-lightweight concrete mix was successfully produced using lightweight aggregates produced from mixed masonry rubble in a thermo-chemical process. The physical and mechanical characteristics of this mix closely resemble those of a reference mix designed analogously using expanded clay. The typical characteristics of infra-lightweight concrete described in the literature, such as its low dry bulk density, moderate strength, low thermal conductivity, and high freeze-thaw resistance, are achieved. This shows that the novel lightweight granules can be used not only as lightweight aggregates for lightweight concretes [32], but also in infra-lightweight concrete.

Acknowledgements

The “REALight” research project (grant number 033R257) was funded by the Federal Ministry of Education and Research (BMBF) as part of the “Resource-efficient circular economy – Construction and mineral material cycles (ReMin)” funding guideline. “ReMin” is part of the BMBF research concept entitled “Resource-efficient circular economy” and aims to implement resource-efficient construction and the extensive use of secondary mineral raw materials from construction waste, slag, ash, and mining residues.

REFERENCES/LITERATURE