Long-standing cooperation with Lacobas in Moldavia bears fruit

Since 2003, the Lacobas Construct company has been operating in the building materials market of the Republic of Moldavia with success. Meanwhile, Iacobas Construct has developed to one of the greatest and most well-known manufacturers of concrete products in the Republic of Moldavia.

With machinery and accessories of suppliers from throughout Europe, cutting-edge and most efficient technology on international standards is used in the production of concrete blocks.

In addition, the team of Iacobas is constantly working on new projects and is developing new technologies and products. In line with the current trends, they create products that are also optimized regarding the price-performance ratio on the highest level of quality.

Thanks to this wide range of high-quality products, Lacobas Construct now takes the leading position among the concrete block manufacturers in the Republic of Moldavia.

15 years of successful cooperation

In the course of the last 15 years, the cooperation with the equipment manufacturer Frima GmbH & Co. KG located in Emden was a key contribution to success.

An existing OMAG block making machine was replaced by a Frima HP1200 block making machine and a new bucket conveyor in 2010. The concrete mixing plant was modernized at the same time, too. The control system of the same was replaced and the mixing plant was equipped with the latest measurement and control technology. Moreover, the wet line and dry line were modernized. All old equipment parts such as finger car, elevator and lowerator, slideways, chain conveyors, packaging unit, roller conveyors, pallet magazine and board package buffer were retrofitted and updated. Afterwards, the equipment was completely rewired and provided with a new overall control system. The cornerstone of the Iacobas Construct company, as it does exist today, was laid by this intervention.

In 2018, a used block making machine built in 2008 was installed at Lacobas Construct. This machine was now in 2024/25 provided by Frima with a new vibration table traverse and a vibration table of the latest generation of servo technology, which improved the quality, compaction and efficiency considerably. As part of this conversion, a continuous running rail with wear treatment between the first filling and the second filling was integrated, which provided the filling trolleys with guidance in the section of the mold and reduced the wear and tear on the mold and filling trolleys significantly. In addition, the previous washing system of this existing plant was replaced by an ultra-modern Frima wash system in 2024, with enhancing the quality of the washed products essentially.

Second production line supplied in 2022

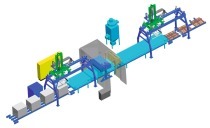

In 2022, the second Frima HP1200 complete production line was supplied, equipped with cutting-edge technology. Due to the interaction of the latest generation of servo technology and real-time measurement system with hydraulics and process engineering, Frima managed to ensure a nearly 100 % exact repetitive accuracy. This is reflected in the quality, compaction and efficiency. As color mix systems and a highly modern wash system are part of the equipment, it is now possible to manufacture all concrete goods of the product portfolio. The state-of-the-art visualization allows to operate the complete production line on several PCs. Plant parameters, recipes, data tracking is possible there as well as their storing. In addition, the visualization system allows adjustments to be carried out in real time via the Frima online support.

On the dry line, a packaging unit provided with the latest control technology and hydraulic gripper was installed, to ensure 100 % repetitive accuracy on this side as well. Furthermore, a modern mobile sliding table was installed, to push all products to the required packaging sizes.

The complete production line with the Frima HP1200 machine is one of the most powerful plants in the field of concrete technology due to its high efficiency at low maintenance expenditure.

Recently additional extensions and modernization

In 2025, a new board package buffer was incorporated into the Frima HP1200 machine supplied in 2022 so as to achieve an even higher degree of efficiency. Due to transferring board package in and out, different cycle times on the wet line and on the dry line are now possible, allowing the manufacture of various products without interferences during production. Thus, the Frima HP1200 is excellently equipped for the future through this extension.

In 2025, eventually, the old chamber section of the first Frima HP1200 supplied in 2010 was extended and modernized. The scope of modernization also included the replacement of the old elevator and lowerator as well as the finger car.

Retrospectively, the targeted measures through modernizing old components and extensions with equipment parts and new equipment using state-of-the-art technology, Lacobas Construct turned into a leading premium concrete block manufacturer in Moldavia.

This process with the associated technologic and economic development has been attended by Frima GmbH & Co. KG over the last 15 years and was strongly characterized by the close and trusting cooperation between the companies Lacobas Construct and Frima.

CONTACT

Frima GmbH & Co. KG

Stedinger Str. 12

26723 Emden/Germany

+49 4921 584-0