Malaysian industry leader implements cutting-edge automation solutions with European engineering expertise

Riding the waves of change in the Malaysian construction industry, IJM Corporation, one of the largest conglomerates in Malaysia, decided that it is time to expand its business into prefabricated building systems commonly known as Industrial Building Systems (IBS) in Malaysia. Operating as IJM IBS, a fully-owned subsidiary of IJM Corporation, this pioneering business is based in the thriving industry hub of Bestari Jaya, Selangor. By integrating state-of-the-art Industry 4.0 technology from Progress Group, a European market leader in precast manufacturing, IJM IBS presents a revolutionary “Smarter Way to Build.”

Transforming the future of construction

Issues that are plaguing today’s construction industry, such as low productivity, skilled labor shortage and increasing demand for better quality homes, can now be overcome by adopting the IJM IBS precast system. IJM IBS offers a comprehensive end-to-end precast building solution, covering design, costing, fabrication, delivery, and on-site installation. With a focus on sustainability and innovation, IJM IBS is well-positioned to capitalize on opportunities emerging in these areas. The strategic collaboration with Progress Group, one of the leading companies in precast automation systems, amplifies their capabilities. Progress Group, equipped with cutting-edge machinery, software, and their own precast plant, shares a common mission of creating better living conditions. This partnership enhances IJM IBS’s ability to deliver advanced solutions, setting new industry standards.

Precast: Building the future

The precast concrete market, driven by factors such as increased demand for affordable housing, urbanization, environmental concerns, and technological advancements, offers a diverse range of products. IJM IBS plays a key role in this landscape, offering a wide array of elements, including columns, beams, slabs (BubbleDeck/half slab/full slab), plain wall panels, customizable patterned wall panels, bathroom units, staircases, architectural elements, and more. These precast elements allow for faster, safer, and more efficient construction while reducing waste.

Across Malaysia, offices, warehouses, factories, and high-rise residential projects have already embraced this innovative approach. Furthermore, numerous government projects such as schools, hospitals, civil servant quarters, and offices are currently in progress, showcasing the expanding reach and potential of precast concrete in the construction sector.

Pioneering sustainability in construction

With their state-of-the-art plant and innovative approach, IJM IBS sets a new standard in top-quality precast production while minimizing waste. Leveraging cutting-edge technology and streamlined processes, they have achieved an impressive waste percentage of less than 1.0%. This environmental focus not only benefits our planet but also enables IJM to produce precast components with enhanced efficiency and cost effectiveness.

In-house automation delivers customized solutions

Utilizing advanced automated machines, IJM achieves precise in-house production of reinforcement wires and mesh exactly to specifications. Cutting-edge technology, such as the M-System Evolution mesh welding plant equipped with a magnetic lifting beam for automated logistics, ensures accurate opening cuts and bar spacing. The EBA stirrup bender bends wires precisely based on design data, eliminating the need for manual labor. The outcome is a customized mesh ready for casting, requiring minimal additional adjustments and enhancing efficiency.

Effortless automation optimizes production cycle

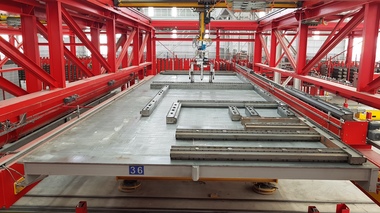

Utilizing cutting-edge automated machinery from Progress Group, IJM IBS has achieved a seamless production process that leaves no room for imperfections. These state-of-the-art machines handle each stage with precision, from securing the mesh to transferring it onto the pallet, and even employing robotic assistance to position magnetic shutters. The result? A remarkably streamlined production cycle with minimal human intervention.

These remarkable machines boast the ability to simultaneously compress, compact, and vibrate the slab on the pallet, resulting in an impeccable finished product. The Form Master, responsible for shuttering and de-shuttering, alongside the storage robot, handles the shutters in a fully automated manner, contributing to enhanced precision, accelerated operations, and even greater cleanliness thanks to the addition of a pallet cleaning device.

Furthermore, IJM IBS has revolutionized its work environment by installing pallet lifting and transport equipment, which significantly reduces the burden of heavy labor, creating a more appealing workspace. Likewise, the fully automated tilting equipment effortlessly tips the entire pallet, showcasing IJM’s commitment to efficiency and ease.

By implementing a concrete spreader that only utilizes the necessary amount of concrete, as determined by advanced software directly communicating with the machinery, IJM IBS drastically reduces concrete waste. This innovative approach not only contributes to environmental sustainability but also showcases its commitment to responsible resource management.

Lastly, the power trowel employed expertly smoothens the surface, elevating the overall quality of the product to new heights. Through this meticulous attention to detail and unwavering pursuit of excellence, IJM demonstrates its dedication to delivering flawless results that surpass industry standards.

Digital factory

Progress Group also supports IJM IBS as a partner on their way to a digital factory. The broad product portfolio of software solutions from Progress Group, based on the three pillars BIM, ERP and MES, guarantees perfect integration of all business and production processes from a single source. IJM was already able to achieve a higher efficiency in their automated plant with Progress’s specialized MES software, ebos. ebos is a complete software solution for work preparation, production and process management, control and analysis that delivers an overall picture of the entire production process. Beyond that, the mobile application mebos makes it possible to easily handle storage control and manual adjustments in the external warehouse. In addition to the MES system, IJM also chose Progress’s ERP solution erpbos, which was developed specifically for the precast concrete industry. The complete process chain can be managed in erpbos, allowing IJM to always have a complete overview of its business and performance. Due to the openness of the Progress software, it was no problem to interface erpbos to SAP, which is used as a company-wide ERP system for finance and procurement. A central digital platform now ensures that anyone can access the data from anywhere, ensuring 100% transparency. The project life cycle is constantly updated, making it possible to make decisions in real time and keep costs and time under control. Accurate resource planning and consumption control as well as optimal production planning significantly increase productivity and prevent production downtime thanks to always up-to-date stock levels.

Chan Huan Ong, Assistant General Manager at IJM IBS SDN. BHD., expressed satisfaction with the collaboration, stating, “We are thrilled with the Progress Group automated machinery. It has significantly improved efficiency, quality, flexibility, safety, and cost savings in our precast concrete component production.” He further described the collaboration as mesmerizing, calling it “simply a Smarter Way to Build.”

CONTACT

IJM IBS SDN. BHD.

Wisma IJM Annexe,

Jalan Yong Shook Lin,

46050 Petaling Jaya,

Selangor/Malaysia

EBAWE Anlagentechnik GmbH

Dübener Landstraße 58

04838 Eilenburg/Germany

+49 3423 6650

Progress Maschinen & Automation AG

Julius-Durst-Straße 100

39042 Brixen/Italy

+ 39 0472 979100

Progress Software Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979159

INFOBOX

IJM Corporation Berhad was founded in 1983 in Malaysia. It started as a small construction company and has since grown into a diversified global enterprise with operations in construction, property development, manufacturing, port, and infrastructure. Today, IJM Corporation is one of the largest conglomerates in Malaysia and has a presence in over ten countries around the world.