Material saving, stress-oriented carbon reinforcement for precast construction

Apart from many advantages as against reinforcement steel, the high materials costs are a crucial disadvantage of carbon reinforcement. Therefore, it is reasonable to develop manufacturing methods which allow a reduction of the material requirements.

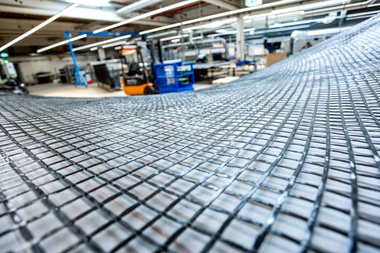

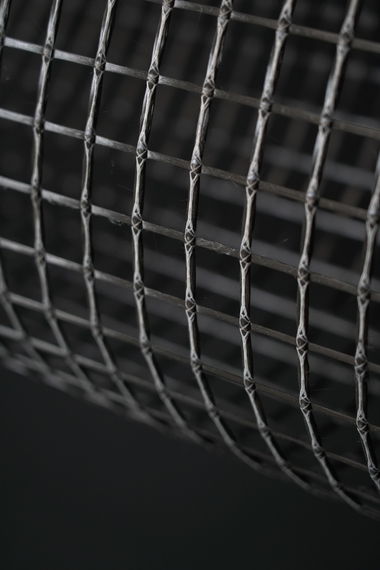

For this reason, the Unit of Concrete Structures and Bridge Design at the University of Innsbruck has been dealing with the production of carbon reinforcement for 10 years, using the so-called Tailored Fiber Placement procedure and the use of the same. In this process, the functional material is fixed by means of a fixing thread on an embroidery fabric which is removed as soon as the reinforcement grid has been finished. The automated process enables efficient production with low material consumption.

The advantages of TFP include angular independence, possibility of multi-dimensional alignment, near-end-shape manufacturing, and high position accuracy. These advantages were illustrated for different demonstrators where the reinforcement was placed along the main tension trajectories.

Insert parts with a concentrical, circular reinforcement configuration were developed for a concentrated load transfer into precast elements. The test revealed that owing to the inserts, a substantial increase in the load-bearing capacity as against reference tests, using conventional fastening systems, could be obtained.

The use of a carbon reinforcement eliminates the problem of corrosion, allowing the application of material-saving designs. Thus, a concept for an edge beam was developed which reduces the required concrete cubage significantly. The reinforcement cage was assembled by planar and angular grids being manufactured in a TFP process. Due to the good coordination of concrete and reinforcement in combination with the in-plant production, it was possible to design the edge beam in a high quality.

With the aid of the demonstrators, it can be shown that TFP allows the production of slender, durable and above all material-efficient precast elements made of carbon-reinforced concrete.