Millable recyclable concrete for additive manufacturing of forms for free-form precast elements

In recent years, the demand for high-quality, free-form precast elements has increased continuously. Polystyrene milling is a leading manufacturing technology for producing the necessary shapes. Producing many unique, geometrically complex shapes incurs high costs and generates enormous material waste, thus reducing cost efficiency and increasing the environmental footprint. This is why a material was developed that is printed close to the final contour and subsequently milled into shape. The resulting casting model is then molded using a suitable casting resin. This mold is used for the production of precast elements, and the printed and milled model can be recycled and returned to the material cycle.

Various rheological and mechanical tests were carried out to characterize the extruded concrete and the influence of the recycled material on it. These included the determination of the flowability using the Haegermann spreading table according to DIN EN 1015-3

as well as the compressive and flexural strength according to DIN EN 12390-2 and DIN EN 12390-5, respectively. These tests proved the successful use of the recycled material for the substitution of the rock powder used in the initial concrete mix design without compromising the mechanical properties.

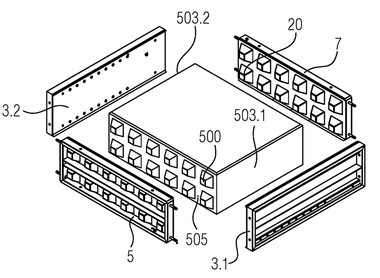

Resource efficiency and sustainability are of major importance, which is why this technology will be primarily used in prototyping and small-sized series. These fields of use provide high potential for saving resources in form-making due to the uniqueness of the components. The development and implementation of the new formwork system is a key success factor for the efficient production of precast elements.