Practical guidance for using fiber-reinforced polymer (FRP) reinforcement in compression

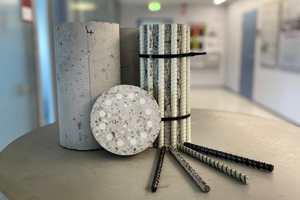

Using non-metallic reinforcement based on fiber-reinforced plastics (FRP) is on the rise throughout Germany, at the latest since the introduction of the corresponding DAfStb guideline in early 2024. While the high tensile strength and the advantageous durability properties of FRP reinforcement have been thoroughly researched for many years, the material behavior in compression is still widely unexplored.

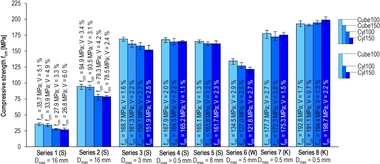

Research findings obtained at the Institute for Solid Structures at TU Darmstadt show the potential of such reinforcement in compression. Compressive strength and elastic modulus in compression of FRP reinforcement bars with different fiber-matrix combinations were investigated in detail. While the modulus of elasticity in compression corresponds to that in tension with negligible deviations and regardless of the type of FRP tested, no such general conclusions can be drawn regarding compressive strength. Owing to the complex compressive fracture behavior, parameters such as the fiber diameter or the shear modulus of the matrix are crucial. In general, tested FRP reinforcement bars based on glass fibers showed the highest compressive strength, while carbon bars showed the lowest values.

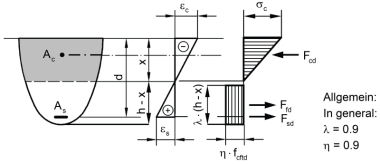

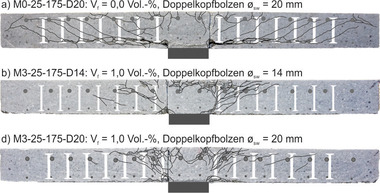

In addition to the pure investigation of the material behavior of the FRP reinforcement in compression, reinforced concrete specimens were also tested experimentally. Based on these results and a test database from the literature, it was possible to reliably derive design diagrams, which are available for various cross-sectional geometries and enable the realistic design of FRP-reinforced columns.