QualiMaster RT1 – Consistency measurement in the Eirich mixer

Rheological measurement in the mixer presented by Ei-rich demonstrates a technology that has been shortlisted as one of the finalists for the bauma Innovation Prize. Eirich has integrated the function of the rheometer in the mixer (in-situ measurement). The product is marketed under the name QualiMaster RT1. A rheological measurement can take place directly after preparing the concrete in the mixer to determine parameters for the yield point and the dynamic viscosity, and derive on this basis the consistency of the concrete.

Quality increase and digitization for meeting the challenges of the future for concrete

Currently, the demand for CO2 saving confronts the concrete and cement industry with major challenges. To improve the CO2 balance of concrete, cement is partly replaced by fine-grained substitutes. Furthermore, part of the particles can be exchanged with recyclates. If adjusting the flow properties with standard cement is already a challenge, the difficulties are increased when substitutes replace cement and particles.

In addition, strict demands are placed on the flow properties for high-performance concretes, such as SCC (self-compacting concrete) for reliably casting complex geometries without disintegration. Here, too, the flow property of the fresh concrete is strongly influenced by the type and quantity of the fines content used.

Consistency is typically determined by standardized measurement methods such as slump flow or V-funnel flow time. A disadvantage of these methods, according to the supplier, is that they are carried out manually and, moreover, cost valuable time. Rheological measurement in the mixer saves time, and the flow properties are determined independently of persons. Measurement takes place directly following preparation of the concrete in the mixer. No sampling is necessary. Subsequent adjustments of flow properties – e.g., by adding additional admixtures and directly after intermixing – mean that new measurements can be carried out directly afterward, since the entire batch remains in the mixer.

Control extension enables in-situ measurement

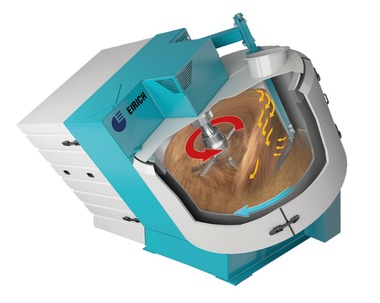

The Eirich Intensive Mixer consists of a rotating pan and an eccentrically mounted mixing tool – the rotor – whose speed and direction of rotation are variable. The wall scraper and the rotating pan deliver the material to the rotor, which carries out the actual mixing task.

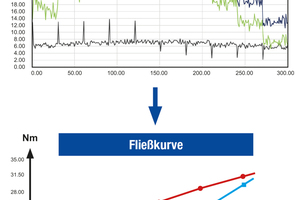

For rheological measurements in the mixer, however, the mixing pan still stops and only the mixing tools rotate. The functional principle is thus identical to a rotation rheometer with rotating measuring body (Searle principle). The setup and performance of measuring methods, as well as the analysis, take place by means of the mixer control. This control extension makes it possible to individually and flexibly set up standard measuring methods such as ramps or stepped profiles. The measured results are directly entered as characteristic date and furthermore remain available in the long-term storage medium. The measured and averaged values are automatically shown in the flow curve (value pairs for torque are obtained from speed). The regression function may be chosen either according to Bingham or Herschel-Bulkley to obtain the characteristic parameters for viscosity, yield point and thixotropy, which correlate with the standard measuring methods, e.g. based on the slump flow.

Simple and fast method with maximum benefit

With the values calculated, fluctuations in various charges in a formula can be determined. This offers the concrete technologist a tool for controlling concrete batches within very short time and therefore delivering constant quality, despite fluctuating initial constituents.

CONTACT

Maschinenfabrik Gustav Eirich GmbH & Co. KG

Walldürner Str. 50

74736 Hardheim/Germany

+49 6283 510