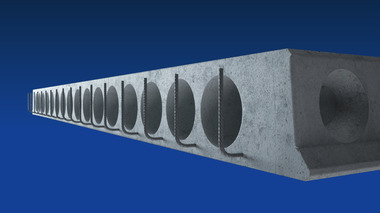

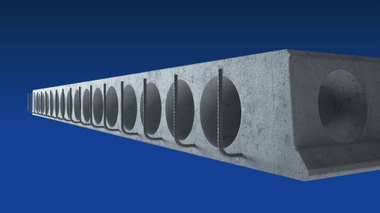

Reuse instead of recycling: Reuse of prestressed concrete hollow-core floor slabs

In cooperation with the Bundesverband Spannbeton-Fertigdecken e. V. (Federal Association for Prestressed Precast Concrete Floors), the Department of Concrete Structures and Structural Design at RPTU conducted a research project on the reuse of prestressed concrete hollow-core floor slabs. The experimental comparison of new and deconstructed prestressed hollow-core slabs was to evaluate their reusability. Kastell GmbH initially installed a sample floor consisting of eight prestressed hollow-core slabs with ring tie, which was deconstructed after 69 days of loading at 5 kN/m². As an alternative to conventional grouting of the longitudinal joints between the prestressed hollow-core slabs, connections such as shear pockets or grouting including pre-treatment with mould oil were tested to facilitate reversibility, which significantly improved the elements’ suitability for non-destructive deconstruction.

Four of the deconstructed prestressed hollow-core slabs were assessed experimentally and compared with three previously unloaded slabs from the same production batch in four-point bending tests conducted at the RPTU’s structural engineering laboratory. Above the calculated ultimate limit state, the deconstructed hollow-core slabs exhibited slightly lower flexural stiffness than their initially loaded counterparts and failed at lower load levels with reduced deflections. Besides optimizing detachable connections, the causes of these differences deserve more thorough investigation. However, since these deviations in structural behavior only occurred above the calculated load-bearing capacity, the performed tests confirm the fundamental potential of prestressed concrete hollow-core slabs for reuse at the structural component level.

![Fig. 1: Deconstructed prestressed concrete hollow-core slab in the test rig [1]](https://www.bft-international.com/imgs/2/2/0/6/6/5/2/tok_28cb39a6745bf656b5c8517c19df637a/w300_h200_x600_y400_4_2_Mueller_Abb-329f31ef19ae1710.jpeg)