Schares uses Enerpac jack-up system for challenging Berlin concrete bridge removal

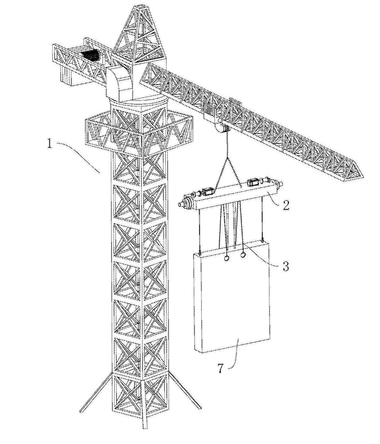

German heavy lift contractor, Autokrane Schares GmbH, has completed its first bridge project using the company’s new Enerpac JS-250 jack-up system. The compact lifting system assisted in the removal of a section of the Marggraff bridge over the Britzer Verbindungskanal in Berlin.

Lack of space and busy road intersection

First built in 1965, the Marggraff bridge comprises three bridge sections built adjacent to each other. Autokrane Schares was responsible for removing the first 60 m long bridge section weighing 1,500 metric tons. The presence of overhead power lines and lack of space at the busy road intersection meant that an Enerpac jack-up system was the preferred lifting solution.

To position the JS-250 jack-up tower bases on the narrow canal towpath, a section of bridge deck was removed at each end of the bridge and the jack-up bases lowered onto the path, followed by the header beams. Once the jack-ups and header beams were in position, additional jack-up tower barrels were added from a pontoon. Synchronous lifting of the bridge section was achieved using two interconnected split flow pumps.

The bridge deck was removed in three stages, each 60 m in length and weighing between 450 and 630 metric tons over a two-week period. For each stage, the JS-250 raised the bridge deck 3 m clear of the bridge abutments. Two pontoons were positioned underneath, and the bridge deck lowered onto steel frames resting on support structures. The bridge was then floated to the side and lowered on to SPMTs for transportation by road to a nearby site for dismantling.

Precise operations necessary

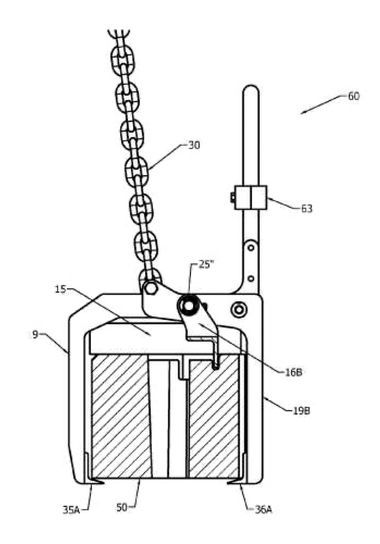

The close proximity of a busy highway meant that precise operation of the JS-250 was critical. As standard, the JS-250 features an adjustable top barrel, including a double-acting lock nut cylinder with swivel saddle, for each of the four lifting towers. The cylinders can be extended, allowing precise adjustment of the starting height of each leg, ensuring safe and stable lifting.

“Space restrictions at the site made this a very challenging project,” said Max Boere, Team Leader SPMT, Autokrane Schares. “The compactness and ease of set-up, together with accurate synchronized lifting, made the Enerpac JS-250 a perfect fit for this project.”

Enerpac JS-250 jack-up

The Enerpac JS-Series jack-up system is a multi-point lifting system comprising four jack-up towers, one positioned under each corner of a load. The lifting frame of each jack-up tower contains four hydraulic cylinders, which lift and stack steel barrels. The load is lifted in increments as barrels are inserted via an automated system and stacked, forming the lifting towers. Managed by a single operator, each tower’s lifting and lowering operations occur simultaneously, while the jack-up’s synchronous technology maintains the balance of the load.

CONTACT

Enerpac World Headquarters

P.O. Box 3241

Milwaukee, WI 53201-3241/USA

N86 W12500 Westbrook Crossing

Menomonee Falls, Wisconsin 53051

+1 262 293 1500