Serial and modular system construction method – a contribution to sustainable building with concrete

Goldbeck GmbH is one of the major and most innovative construction companies in Europe. It is therefore hardly surprising that Goldbeck is also at the forefront of the topic of “sustainable building with concrete.” Goldbeck, in its sustainability strategy, has committed itself to the objective to present on a corporate level a CO2 neutral balance already in 2023. To reach this objective, the essential focus in the area of “building with concrete” is on three fields of activity:

Building system / building elements,

Technology / innovation,

Optimization of transports.

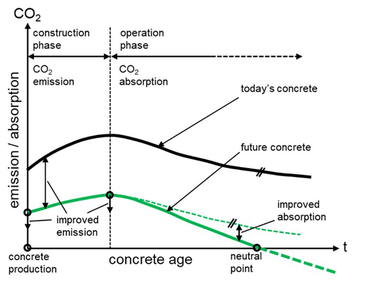

In building with system, which Goldbeck has perfected since the foundation of the company, the structural components of a building can be optimally coordinated. In-house prefabrication of the structural components has considerable advantages over casting the concrete in situ. The result are geometrically optimally coordinated structural components produced in steel forms with minimum use of material. In the area of technology and innovation, both product and production are optimized. From introduction of 3D-printed concrete, preparation of concrete mixtures to CO2-optimized mix formulas to substitution of reinforcing steel - the most diverse approaches are researched and implemented in operational practice.

Transport of the structural components manufactured in plants produces not insignificant amounts of CO2. For this reason, Goldbeck also examines this topic. In addition to classical truck-transport optimization, increased utilization of railroad transports and innovative railroad concepts are examined. Furthermore, new drive concepts for trucks are being tested. In conclusion it can be said that many additional approaches are here and in particular in the area of building needed for improving the sustainability of the construction material concrete still further.