Successful paving block production using low-carbon circular cements on an industrial scale

Germany is already reusing 95 % of construction and demolition debris. The ReConcrete technology of Heidelberg Materials pursues a further-reaching innovative approach of purposeful carbonation of the hardened cement paste recovered, which binds the CO2 permanently in RCP.

Germany is already reusing 95 % of the construction and demolition debris. When recycling demolished concrete, the raw materials recovered in this process are often of a lower quality than that of the initial products. These materials are primarily used in road construction, for example, as frost protection layer. However, recycling is able to do more.

By innovative techniques of processing, the demolished concrete can be decomposed to its constituents almost separated to type. It is possible to reuse all of the sand and gravel recovered in this process for the production of high-quality concrete [1], with being a most promising contribution to circular economy.

In addition, the fine fractions occurring in the recycling process, namely the hydrated hardened cement paste (recycled concrete paste, RCP), can be separated. The recovered hardened cement paste can be used as raw material in the production of bricks as well as cement. This not only conserves natural resources, but also reduces the carbon emissions in the manufacturing process.

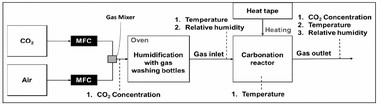

The ReConcrete technology of Heidelberg Materials pursues a further-reaching approach of purposeful carbonation of the hardened cement paste recovered. By the addition of CO2, the pulverized cement paste can be carbonated in a downstream chemical process, which binds the CO2 permanently in RCP [2]. RCP processed in this way not only acts as a carbon sink, but also suits as high-quality addition in the production of cement and concrete [3].

Recycling can do more

The effect of the carbonation of RCP and its use in cement and concrete is positive twice. On the one hand, it contributes to binding of carbon and, on the other hand, it allows for using Portland cement clinker in composite cement, which saves about one ton of carbon per ton of this carbonated RCP [3]. This saving is made up of two main factors:

Mineralized carbon: Binding of carbon in RCP achieves savings of about 150 kg of carbon per ton of RCP.

Replaced Portland cement clinker: The use of RCP replaces Portland cement clinker1:1, in the production of which 800 - 850 kg of carbon per ton may occur.

Apart from calcium components, RCP also contains aluminum and silicon components. These constituents are released in the chemical process of carbonation and produce an x-ray amorphous gel (see Figure 1). When reusing the carbonated RCP in cement or concrete, this gel acts like pozzolana. Pozzolanas are materials that are characterized by their reaction with lime, making a contribution to the strength of the cement and concrete.

As part of the „C2inCO2 - Calcium carbonation for the industrial use of CO2“ project funded by the Federal Ministry of Education and Research (Funding code 033RC026) tests were carried out for investigating the feasibility and efficiency of RCP carbonation on a larger scale, among other things. Within this project, the approach was implemented for the first time on a semi-industrial scale, producing several tons of carbonated RCP. An important part of the project was the examination of a cement containing the carbonated RCP as addition in the production of concrete paving blocks.

Approx. 2 tons of separated RCP were carbonated in a so-called flash reactor on a pilot scale by the project partner Thyssenkrupp Industrial Solutions AG (Beckum/Germany).

Testing in the laboratory

The aim was to develop a cement with a maximum of 65 % Portland cement clinker. A cement containing granulated blast-furnace slag was chosen as initial cement. The addition of carbonated RCP allows reducing the proportion of Portland cement clinker and granulated bast-furnace slag. This results in both ecological and economic advantages.

In the first step, this initial cement was mixed with 15 % carbonated RCP and its water requirement, setting, and compressive strength were tested in accordance with EN 196 in comparison to a CEM II/B-S 42.5 N reference cement (see Table 2).

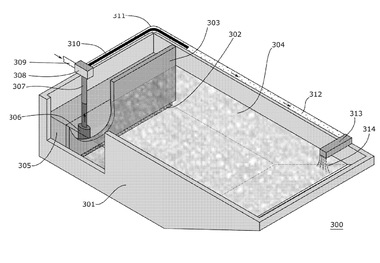

In another laboratory test, no-slump concrete mixtures were made to simulate an application in the production of paving blocks. For investigating the compaction behavior and the compressive strength, test specimens were produced with the aid of the IC tester of Galileo. After the production, the test specimens were shrink-wrapped and stored for 24 hours at a constant temperature of 30 degrees C. After the storage period, the compressive strength was determined.

The test specimens being made of the no-slump concrete mixture with the trial cement showed a slightly higher compressive strength, similar to the result of the mortar testing. This indicates that the trial cement is suitable for the planned production trial and that the concrete mixture exhibits a satisfactory strength.

Testing in practice

Practical tests were conducted at the Iffezheim factory of Kronimus AG Betonsteinwerke and comprised two production trials. The first trial was conducted to substitute the normally used cement completely by the test cement (compare Table 1). In the second trial normally used cement was applied, however, the commonly used filler was substituted by the carbonated RCP.

Apart from the concrete composition, above all the machine setting has a significant influence on the product quality. This paper does not refer to the various setting parameters in detail. It should be noted, however, that no adjustments on the machine settings had to be made for both test mix designs. Afterwards, the paving blocks manufactured were stored for hardening together with the regular production, then they were palletized and shrink wrapped.

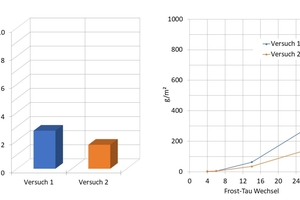

At the age of 28 days, both production series exhibited excellent results in relation to the tensile splitting strength, compressive strength, and freeze-thaw and de-icing salt resistance in accordance with standard EN 1338 Annex D and DIN CEN/TS 12390-9. The obtained tensile splitting strength significantly exceeds the requirements according to EN 1338. The obtained tensile splitting strengths significantly exceed the requirements according to EN 1338. Regarding the compressive strength, V2 is fully in line with the requirement profile of the Kronimus Group. V1 would be described as borderline with regard to the compressive strength. In continuous operation, an adjustment of the concrete mix design and/or an optimization of the machine settings would be necessary here.

The addition of cRCP leads to higher strengths in comparison to the addition of inert limestone powder. This confirms that carbonated RCP is actively involved in the formation of hydration products.

The freeze-thaw and de-icing salt resistance was tested in compliance with EN 1338 Annex D. In addition, the CDF test was conducted in accordance with DIN CEN/TS 12390-9. Both concrete mix designs comply with the most stringent requirement criteria according to EN 1338 and have also passed the CDF test. Weathering after 18 freeze-thaw cycles amounts to 310 and/or 158 g/m², thus being clearly below the permitted limit of 1,500 g/m².

Conclusion

Concrete can become more environmentally friendly and sustainable by modern recycling methods and a selective processing of the same. A most promising approach is the separation of the hardened cement paste (RCP) and its carbonation in a chemical process.

This process allows permanent binding of carbon in the form of calcium carbonate. The carbonated RCP produced in this way can be used as cement constituent, making an active contribution to the strength development of concrete. Purpose of the funded „C2inCO2“ research project was the examination of this approach on a semi-industrial scale. Carbonated RCP was used for the production of concrete paving blocks, which met all relevant requirements.

As a consequence, the „C2inCO2“ research project makes an essential contribution to the further development of sustainable and environmentally friendly processes in the concrete industry, by researching a new approach for the reduction of carbon emissions and the reuse of concrete waste. Therefore, this approach also helps reduce the application of primary raw materials. It is important that these technologies will be further developed and supported in order to allow their broad application.

CONTACT

Heidelberg Materials AG

Berliner Straße 6

69120 Heidelberg/Germany

+49 6221 481-0

REFERENCES/LITERATURE: