The “Büscher Wall” – Building sustainably with concrete containing recycled constituents

Concrete is an exceedingly versatile construction material, but it is currently facing unprecedented challenges because ensuring a low environmental impact, mitigating climate change and reducing carbon emissions have also become important market drivers. Precast producer Büscher, a business based in Heek in the German Münsterland region, recently came up with a highly innovative solution using top-quality precast elements made of concrete with recycled constituents.

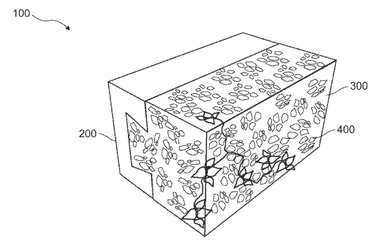

Concrete, the universal construction material of the industrial age, is faced with unprecedented challenges because the rising global demand for primary mineral raw materials is driving prices up. In addition, ensuring a low environmental impact, mitigating climate change and reducing carbon emissions have become important market drivers in the construction sector as well. Any future-proof universal building material needs to be sustainable. Precast producer Büscher, a business based in Heek in the German Münsterland region, recently came up with a highly innovative response to this challenge using top-quality precast elements made of concrete with recycled constituents. Büscher is the only German business to date that was granted a national technical approval, in June 2021, by Berlin-based Deutsches Institut für Bautechnik (DIBt) for precast elements made of concrete in which natural mineral aggregates are fully substituted by recycled materials, according to the producer. In the precast elements forming the “Büscher Wall” system, mixed demolition waste replaces sand and gravel completely. The company is currently building a three-family house in order to demonstrate the additional potential this system can unleash in the future.

“According to a study conducted by the German Federal Association for Building Materials and Industrial Minerals, over 250 million tons of demolition waste are generated in Germany every year,” says managing director Hans-Jürgen Büscher in reference to the current challenge. “Despite this situation, construction waste has so far mostly been used as infill material in road construction and civil engineering. In many cases, such waste is also transported to landfill sites. Predominantly in metropolitan areas, but also in northern Bavaria, municipalities are having a hard time in finding out where to reuse or deposit these increasing quantities.” Consequently, the question arises why such construction waste is not recycled and fully reused as a substitute of primary raw materials in concrete production.

The national technical approval granted to Büscher enables the company to use up to 100% of recycled aggregates including crushed sand similar to Type 3 for its precast elements made of concrete with recycled constituents in exposure classes XC1 and X0 (dry). Under the previously applicable standard, this national technical approval would have allowed the use of coarse recycled minerals of up to 45% for Type 1 aggregates and up to 35% for Type 2 aggregates for mixed demolition waste.

The fact that recycled materials substitute natural mineral aggregates completely enables Heek-based Büscher Group to reduce its carbon emissions by 13%. The “Büscher Wall” thus makes a major contribution to mitigating climate change already during its production.

Demolition waste converted to sustainable construction material

The range of possible applications of the “Büscher Wall” system made of concrete with 100% natural aggregate substitution is exceedingly wide. The Heek-based group of companies was granted the permit to use this material for constructing load-bearing and non-load-bearing interior wall elements up to building class 4, in lengths of up to 11 m and heights of up to 3.70 m.

The origins of Büscher Group date back to 1961 when the concrete plant was set up. At this site, the company produces the complete range of precast elements. Its sister company, Containerdienst Büscher, which is also a group member, deals with the disposal and processing of construction waste. Since the 1990s, the group headed by the two managing directors, Hans-Jürgen and Wolfgang Büscher, and their team of employees have been researching innovative technologies and construction materials with a view to establishing sustainable value chains. The underlying idea is to turn demolition waste into a commercially attractive, valuable material. Its use in the production of precast elements can convert concrete into a sustainable construction material responding to the requirements of the 21st century.

“This is unique and a big step towards a circular economy,” Wolfgang Büscher adds. The group has also implemented this circular economy approach in its day-to-day business – in keeping with its slogan “Büscher – Back for the Future“. The sister company of the precast business, Containerdienst Büscher, also plays an important role in this setting because it provides the means of transport for the delivery of construction waste while also managing the professional processing of the demolition material on the company premises. It is sorted, screened, refined and then recycled into a sustainable raw material for the construction industry. The specially designed, certified production process ensures a consistently high quality standard of the recycled material. Betonwerk Büscher then uses these recycled raw materials for producing high-quality interior wall elements.

Award-winning concept attracts research grants

Implementing this idea requires top-class standards both in the processing of demolition waste and in the production of precast elements. During about eight years of research, Büscher Group has invested large amounts of money in developing these standards and proving their feasibility in terms of quality and cost efficiency. Among other things, the company had to demonstrate the workability of the recycled material and to verify the compressive strength, durability and surface quality of the finished product. In addition to its own experts, the medium-sized company from the Münsterland region also worked with concrete technologists from various universities and research institutions. The German Federal Environmental Foundation (DBU) contributed 250,000 euros to the funding of this project.

In the meantime, the medium-sized precast producer received several awards for this research, including the “Innovation through Research” quality label awarded twice by the Stifterverband für die Deutsche Wissenschaft. In 2019, Büscher Group prevailed against 5,399 other companies in the competition for the most important German business award: The “Grosser Preis des Mittelstands” (Grand Award for Small and Medium-Sized Enterprises) initiated by Oskar Patzelt Foundation honored the Heek-based company’s commitment to doing business sustainably.

Multi-family house as a pilot project

Today, the “Büscher Wall” made of 100% recycled sand and gravel constituents is proving the potential of this new construction material in a real-life project. At Schniewindstrasse in Heek, the first “recycled” house of its kind is being built with paint-ready prefabricated elements made of concrete containing 100% recycled natural mineral substitutes. This project should become a true reference for innovative construction technologies; it was finished in December 2022. While the use of precast elements for constructing residential buildings has previously been considered to be the exception rather than the rule, using elements made of concrete with recycled constituents should prove that the Büscher Wall allows for tailor-made construction while ensuring compliance with relevant sustainability criteria.

This apartment building and the „Büscher Wall” system used for it achieve the target set by Hans-Jürgen and Wolfgang Büscher with pinpoint precision because the project implements exactly the requirements defined by the Federal Minister for Housing, Urban Development and Building, Klara Geywitz, for future-proof residential construction. In view of the housing shortage, rising construction costs and shortage of skilled workers, the member of the Social Democratic Party had recently warned against diluting environmental standards, favoring innovative construction methods instead: “The situation we are in requires us to really think about how to drive down prices,” Minister Geywitz said. “If we want to complete a larger number of residential projects with the same number of skilled workers, the only way to achieve this goal is by embarking upon serial or modular construction.”

The “Büscher Wall” – Perfectly suited for element-based construction

Element-based construction with recycled raw materials – this is what the “Büscher Wall” stands for. Hans-Jürgen and Wolfgang Büscher conceived their pilot project not least because they wanted to convince the construction industry of the system’s advantages as the sector tends to adopt a rather conservative stance when it comes to new manufacturing processes and products. It is thus all the more important for the two brothers to familiarize a great many architects, municipalities, clients and potential construction industry partners with the advantages of the “Büscher Wall”. The hands-on residential project should enable all interested parties to experience the range of applications and benefits of “Büscher Wall” first-hand. In addition, Büscher Group intends to grant licenses to promote the supra-regional use of its precast technology. Interested companies can request further information at .

Hans-Jürgen and Wolfgang Büscher refer to a large number of compelling benefits that speak in favor of the “Büscher Wall” system. After all, the wall elements containing recycled constituents solve several problems at the same time: They achieve savings on purchasing and shipping scarce and costly virgin raw materials such as sand and gravel, and they allow for a genuinely sustainable reuse of demolition waste that is flooding the market in ever greater quantities. According to the Büscher brothers’ estimates, about 200 tons of recycled construction waste can be used to build a single-family home. Finally, the use of precast elements that are designed digitally according to customer specifications, produced cost-effectively and resource-efficiently at the factory, and delivered in paint-ready condition can shorten construction times considerably.

Cost-efficient substitution of primary raw materials

“Our aim is to feed the waste generated during the demolition of old building stock back into the materials cycle to use it as a raw material in the sense of urban mining in order to consume less natural resources,” the two managing directors point out. Complex reprocessing and reuse in concrete production makes the demolition material a sustainable, commercially viable substitute of primary raw materials.

While Hans-Jürgen Büscher had sometimes been ridiculed for this vision in the past, he now concludes that the results of several years of development work and the national technical approval granted by the DIBt are impressive proof of the idea’s feasibility: “Our process makes it possible to produce precast elements with 100% natural mineral substitution.” Only water, cement and a certain ratio of aggregates as required for the particular recipe need to be added. “The entire element then consists of 75% recycled materials. This high proportion is a truly unrivaled achievement.”

Betonwerk Büscher

GmbH & Co. KG

Bült 54

48619 Heek/Germany

+49 2568 388140