Eirich: Dressler precast component factory – a success story

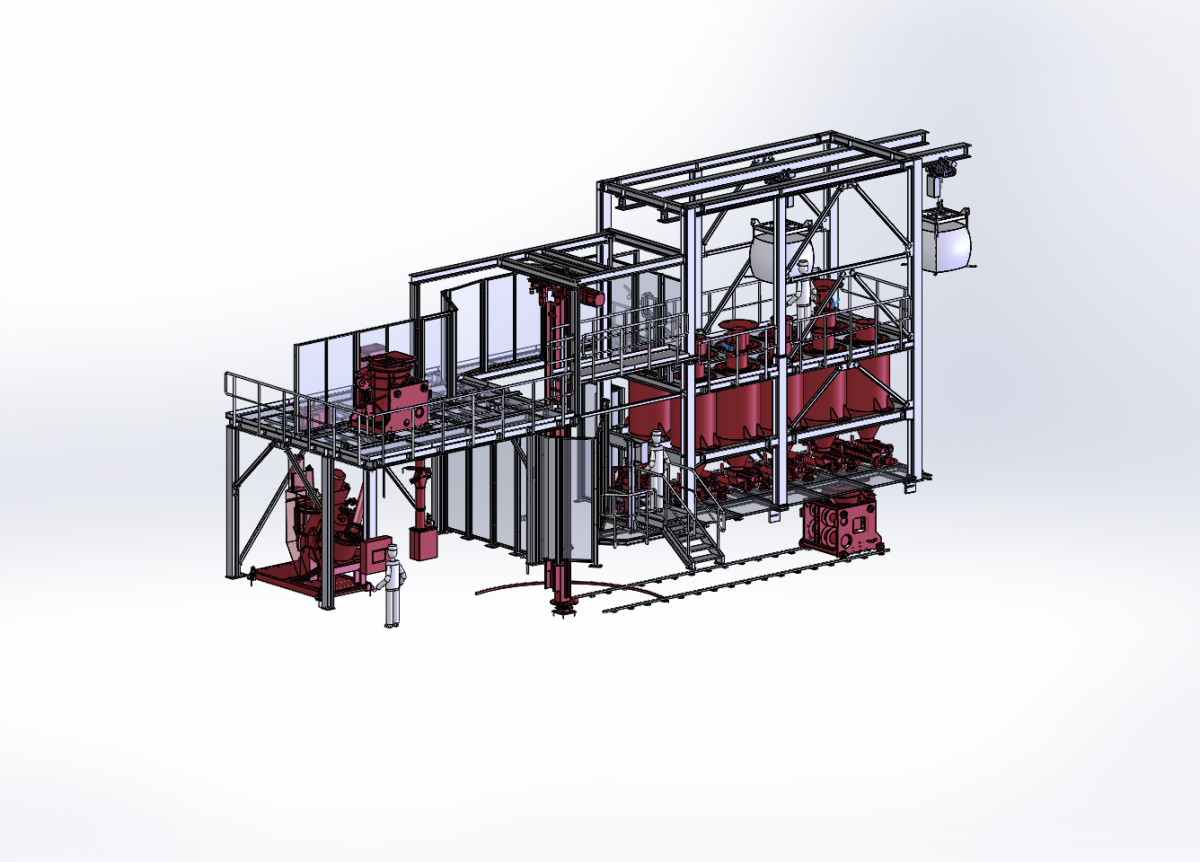

Dressler Bau GmbH, from Aschaffenburg, can look back on over 100 years company history. The development of the precast component factory in Stockstadt has seen EIRICH involved from the very start: 1971 saw the delivery of a complete mixing system, 2001 a mixer with an inclined mixing pan for a better quality of concrete; and 2008 saw the modernization of the control system. Dressler Bau also values the importance of state-of-the-art technology and machinery at all times for the rest of its equipment too, so that it can manufacture precast components of a high quality.

Until just a few decades ago concrete was a functional building material that was improved in visual terms by applying paint, plaster or cladding. Today, concrete has become a highly versatile designer building material. Custom-tailored creative solutions lead to individual construction elements and a diversity of design possibilities. The distinctiveness of contemporary architecture is derived from form, surface and color.

Reproducibly uniform surface coloring

Supplying high-quality precast concrete architectural components is one of the company's specialist fields. Color and surface and edge finishing requirements are getting higher all the time. There is a whole range of completed showcase projects such as, for example, the Tour Total in Berlin, Neues Museum in Berlin, Leitz-Park in Wetzlar or the Eastsite facades, now eight in total, in Mannheim, just to mention a few. Most recently, in 2014, Dressler Bau managed to win the invitation to tender for the architectural concrete facades for the reconstruction of Berlin Palace (the so-called Humboldt Forum) – work on the facades of the Palace Forum and Belvedere is currently in progress. The company also supplies road and rail weighbridges worldwide, along with precast components for obstacle courses, skate parks and climbing facilities for X-MOVE GmbH, which are distributed throughout Europe.

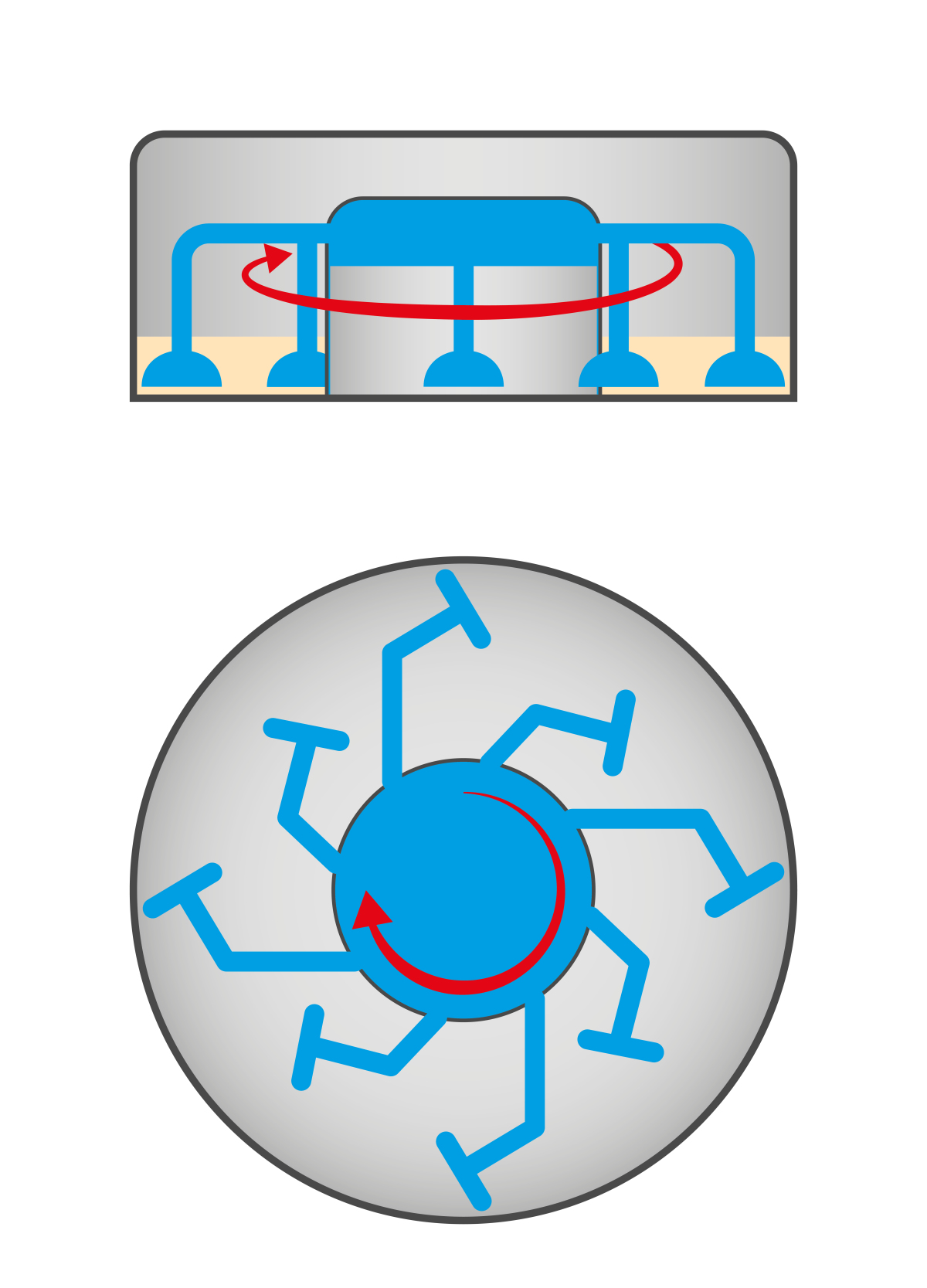

This extensive production program requires the use of different types of concrete; reproducibly uniform surface coloring and air entrainment mean that the fresh concrete has to meet demanding requirements. This is where the strengths of EIRICH mixing technology come into their own; originating from the further development of the ringtrough and planetary mixer, the design of the system makes it possible to achieve higher tool speeds for ensuring more effective cement, fiber or pigment distribution and more homogeneous fresh concrete. This therefore puts the customer in a position to respond with flexibility to all market requirements and to develop new products and thereby secure the long-term success of the company well into the future.

CONTACT

Maschinenfabrik Gustav Eirich GmbH & Co. KG

Walldürner Str. 50

74736 Hardheim/Germany

+49 6283 51603