“Aircrete” used in mobile concrete safety barriers protects vehicle drivers

Safety barriers made of precast concrete components are frequently used as mobile protection elements (e.g. at construction sites). In principle it is true that the more compact and stiffer a barrier wall is constructed, the higher the safety against breaking-through the wall is for a vehicle crashing into it and the protection of persons and material behind the wall. M+V GmbH, the company specialized in safety at construction sites, has now applied for the first time a newly developed concrete – the air-entrained concrete Aircrete – in its precast concrete plant in Kürten (Germany) in cooperation with Heidelberger Beton Rheinland GmbH & Co. KG for manufacturing its mobile precast safety barrier ProTec 120.

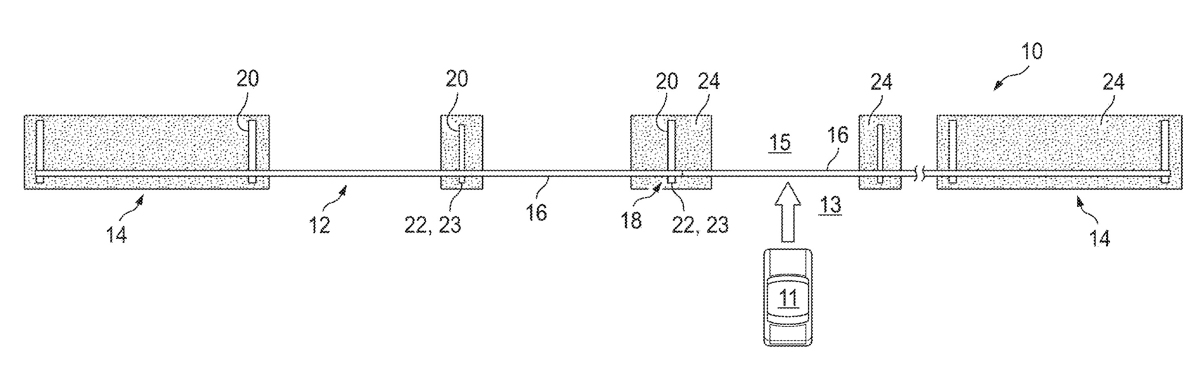

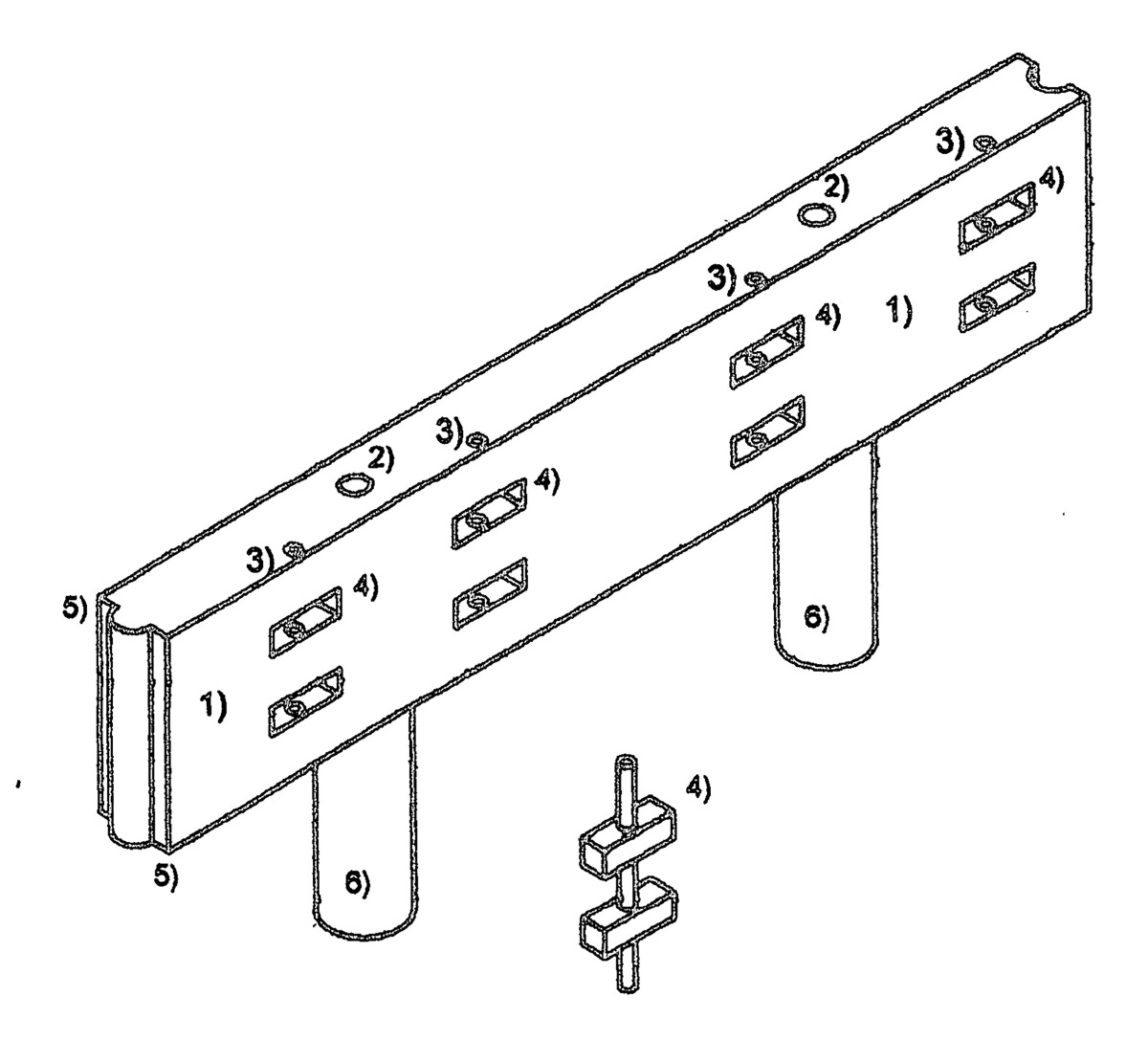

In order to ensure frost and freeze-thaw resistance (XF4), micro hollow spheres are added to the concrete instead of the conventional air-entraining agent. The micro hollow spheres are tiny ready-made air voids consisting of an elastical gas-filled plastic sleeve. Micro hollow spheres create the necessary expansion space in concrete for freezing water and reduce the capillary suction. The product of company Sika – by the name of SikaAer® Solid – has been approved for the German market since October 2007. Aircrete has many convincing advantages in comparison to concrete with conventional air-entraining agents. The air voids are now stable independent of temperature influences as well as processing and installation conditions. The concrete has a lower loss of strength, because of a significantly reduced proportion of total air voids in comparison to conventional air-entraining agents. Therefore, it is easier to realize concretes of strength class C 35/45 and higher. Even free-flowing, easy-to-process concretes such as Easycrete can be manufactured as an air-entrained concrete without any problems. The demands made on concrete meant for the production of concrete crash barriers had been quite high in the precast concrete plant of M+V. It should be easy to process and free-flowing as well as in compliance with the features of exposure class XF4. Aircrete was the solution – the air-entrained concrete with micro hollow spheres. The mobile safety barriers were actually applied at the German highway A 7 between Hanover and Kassel. For the installation a period of just two days was needed for the distance of 5 km. Having an overall height of just 60 cm and an overall length of 12 cm the barrier walls are also suitable for areas with narrow roads. Further benefits: owing to the special design – the concrete is surrounded by a steel section frame – no pieces break out of the safety barrier even in case of an accident. Reflectors, being exteriorly fitted in a protected way in recesses, may not be torn off by vehicles touching the same. Apart from Heidelberger Beton Rheinland practical experiences with the new concrete have already been gained in the region of Nuremberg at companies TBG Franken (Fürth), Betotech Nabburg and FVS GmbH (Wendelstein) and in the region of Weimar at Heidelberger Beton Thüringen (Saalfeld), Betotech Vieselbach and AVS Mellingen GmbH.

Address/Anschrift

HeidelbergCement AG

Berliner Straße 6

69120 Heidelberg/Germany

Tel.: +49 6221 481-0

Fax: +49 6221 481-554

patrick.decker@

heidelbergcement.com

www.heidelbergcement.com