Shockey Precast Group successfully uses Tekla Structures

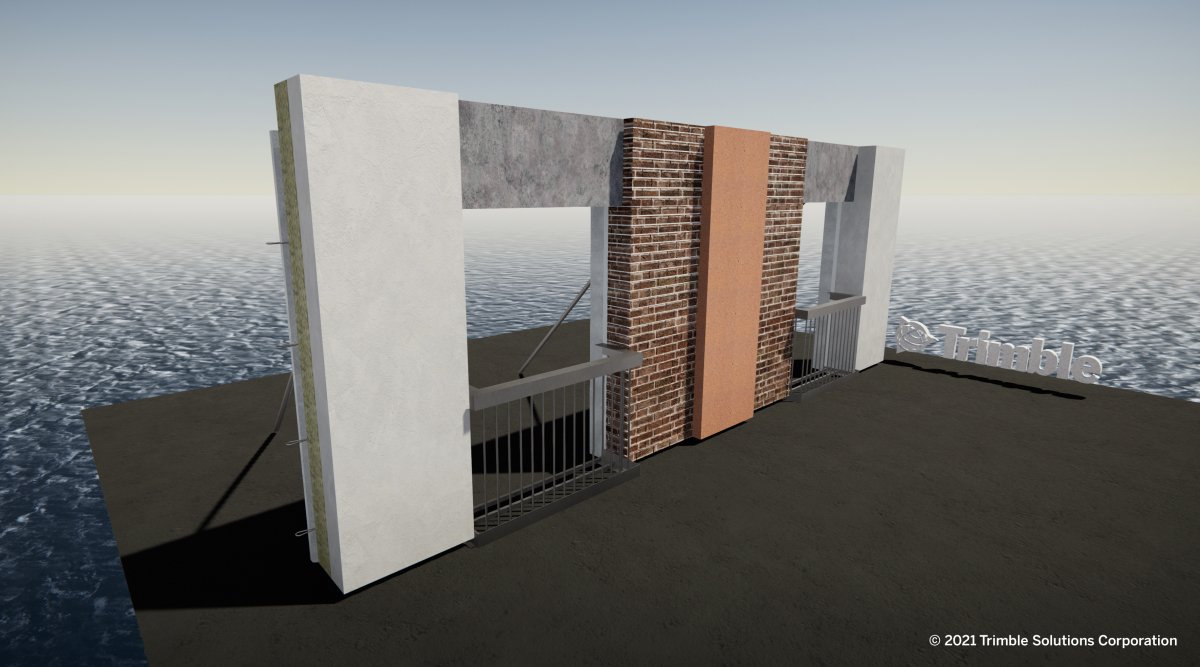

Tekla customers understand the productivity benefits of Building Information Modeling (BIM). As part of the team in building the University of Virginia South Lawn project, The Shockey Precast Group has become one of the first precast concrete fabricators to recognize BIMs impact in working with a General Contractor like Barton Malow.

“BIM was involved from the very beginning,” said Skip Wolodkewitsch, Engineering Information Manager at The Shockey Precast Group. “The contract documents stated that each subcontractor had to provide a BIM model, preferably a Tekla Structures model.” The Shockey Precast Group won the bid partly as a result of showing they could provide all the necessary 3D information. “We know the industry is moving this way, but it was still odd to see the need for BIM integration in contract documents,” added Skip.

After receiving the 3D Tekla model from the steel subcontractor, Skip’s team quickly used that model as a basis to model and align all of their Precast elements. “We shared our progress with Barton Malow every two weeks simply by uploading the model to their website.”

According to Barton Malow Project Engineer Brian Larson, having all the information in the Tekla model to review at once saved considerable time and reduced frustration during the project. “Early in the precast modeling, we had a coordination meeting with Shockey Precast,” Larson says. “Instead of pulling out all the steel and precast drawings to review issues, we reviewed the composite steel and precast model. The number of issues resolved in that short meeting would have taken days if we only had paper drawings!”

“This is just a start,” Larson notes. Analyzing the Tekla structural model for constructability includes, for example, 4D simulations and colorizing on the basis of project data, phasing and scheduling. “For RFIs, instead of trying to create our own sketches of the problem, we attributed any affected pieces in the Tekla model. We then created a Tekla Web Viewer model of the area to attach to the RFI and easily reviewed it on the Internet browser with non-BIM team members. This saved con-siderable time in communicating these issues to the design team.”

“In the future general contractors will be asking us for more information about our pieces. Tekla Structures gives us the flexibility to create our own shop tickets as well as share any necessary information with GCs and other construction team members,” said David Orndorf, Vice President of Engineering at The Shockey Precast Group.

“Clash detection and scheduling is just the tip of the BIM iceberg.” states Alistair Wells, Tekla Inc’s Segment Manager for Precast. “General contractors are already seeing the benefit in using and sharing much more information from the construction team. Eventually, precasters and all other specialty subs will be creating and sharing this kind of information.”

Address/Anschrift

Tekla Corporation HQ

Metsänpojankuja 1

02130 Espoo/Finland

Tel.: +358 30 661-10

Fax: +358 30 661-1500

www.tekla.com