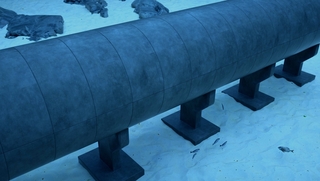

Cortec presents: A Strategy for Concrete-Coated Pipelines

02.02.2024

Figure: Cortec

Figure: Cortec

Subsea oil and gas pipelines are frequently constructed by joining concrete-coated segments together. During construction, concrete-coated pipe may sit for six months to several years before installation.

Capital spares are often ordered at the same time as the initial pipes but with a designed preservation life measured in decades of idle time. To ensure that these capital spares do not deteriorate prematurely, Cortec shares several technologies and tips for preserving concrete-coated pipes from corrosion.

Challenges of Protecting Concrete-Coated Spares

Subsea pipe spares are often stored near the coast due to material handling difficulties. An incredibly long storage period and an aggressive environment combine to pose a frequently overlooked risk for long-term integrity. Although the concrete coating will initially protect the outside of each steel pipe segment, the concrete will absorb moisture, chlorides, and carbon dioxide over time, eventually leading to corrosion. Extreme temperature swings and sporadic inspection intervals can exacerbate the problem. To complicate matters, the concrete coating makes it difficult to access and treat the OD (outer diameter) of the steel pipe.

Migrating Corrosion Inhibitors to the Rescue

Migrating Corrosion Inhibitor (MCI) Technology is typically used to protect reinforcing metals embedded in concrete because of its ability to travel through concrete pores to reach the surface of the underlying metal. The same mechanism makes MCI suitable for protecting the metal pipe OD of concrete-coated pipe. Migrating Corrosion Inhibitors applied to the outside of the concrete pipe can gradually migrate as much as several inches into the concrete to form a protective anticorrosive molecular layer on the steel OD.

When to Preserve Capital Spares

Preservation of spare concrete-coated pipes should be done as soon as possible. Any delay gives moisture and chlorides a chance to start attacking the concrete and steel. Although preservation can be done later, additional rust removal and cleaning may be needed by then. In worst case scenarios, preservation may be neglected so long that corrosion compromises the integrity of pipe segments and new ones must be purchased, defeating the purpose of capital spares.

For more Information click here.

CONTACT

Cortec Europe

Ivana Lucica 5

10000 Zagreb/Croatia

+395 98 277 312