New Master Builders Solutions concrete additives at International AAC Conference

03.09.2018BASF is presenting its broad portfolio of innovative solutions for the aerated concrete industry under its brand name of Master Builders Solutions at the 6th International Conference on Autoclaved Aerated Concrete, which is being held in Potsdam from September 4 to 6, 2018. Visitors can learn about the benefits of concrete additives that improve the entire AAC production process.

MasterCast allows faster and more efficient production. The benefit to the customers is a shorter pre-curing time. In the pre-curing phase of the production, the concrete is expanding and at the same time setting. The reduction in the water content of the concrete ensures shorter setting times. “Concrete additives from the MasterCast series for the production of autoclaved aerated concrete disperse the binder particles efficiently, allowing the water content of the fresh concrete to be significantly reduced,” says Nicoletta Zeminian, Segment Manager Manufactured Concrete at BASF. In addition, MasterCast improves the rheology without impairing the pore formation process. This leads to a significant reduction in the setting time with considerable time savings. By shortening the duration of the pre-curing phase, it is possible to achieve a faster turnover of the molds, leading to an overall acceleration of the manufacturing process and an increase in the productivity of the plant.

Reduction of cement and lime content

Another benefit to the customer is the cost saving, as a result of the composition of the material, which can be changed to a less expensive one. At many plants, the individual production steps have been harmonized with each other to achieve maximum efficiency, therefore the target is not always to accelerate production. In this case, the main advantage of MasterCast is the possible reduction of up to 15 % in the cement and lime content, with no change in the pre-curing time – resulting in significant material cost savings.

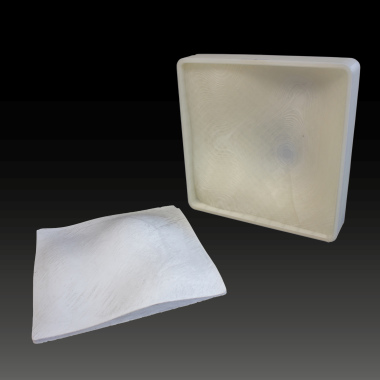

Other products from Master Builders Solutions reinforce this effect and offer additional benefits to AAC producers. The MasterFinish range of release agents allow easier formwork removal and more efficient cleaning and maintenance of formwork in the long term. MasterPel gives the AAC a hydrophobic effect; as a result, it absorbs significantly less water but remains open to the diffusion of air and water vapor, preventing moisture accumulations in the material. Master X-Seed acts as a hardening accelerator, allowing superior efficiency of the production and MasterFiber reduces drying shrinkage and cracking, improves stability and reduces the risk that aerated concrete may fracture during the handling.

For further information on the Master Builders Solutions products, please visit our website at www.master-builders-solutions.basf.co.uk.

CONTACT

BASF plc.

Construction Chemicals

Earl Road, Cheadle Hulme

Cheadle, Cheshire SK8 6QG/United Kingdom

+44 161 485-6222

www.master-builders-solutions.basf.co.uk