A look into the universe: space observatory with façade cladding of precast carbon-reinforced concrete elements

In Niedermuhlern, near Bern, in Switzerland, a space observatory recently opened to the public. The building, designed by the master architect Mario Botta, features façade cladding of precast carbon-reinforced concrete elements. This article is an excerpt from the project report published in the yearbook “Beton Bauteile 2025.”

The Space Eye looks like an over-dimensioned eye high up in the universe. The observatory for space and environment invites you to look, marvel and reflect, all at the same time. Visitors are often amazed even before entering the observatory, in Niedermuhlern near Bern. The shape of the distinctive tower of the Space Eye, designed by the master architect Mario Botta, is modelled on an eye and its unique white façade of precast carbon-reinforced concrete elements immediately catches the eye.

Visitors center for space research

The Space Eye is a multi-media visitors center for space research and sky observation. It places on display the latest in advanced astronomical science and tells stories about the universe – and also about our environment. It accommodates the largest public telescope in Switzerland as well an 8K planetarium. A large exhibition is part of the presentation. As a research and educational center, the Space Eye coordinates research and outreach activities and engages with a high degree of efficiency in the MINT professions, sustainability, digitation and innovative companies.

Precast carbon-concrete concrete elements:

slender and sustainable

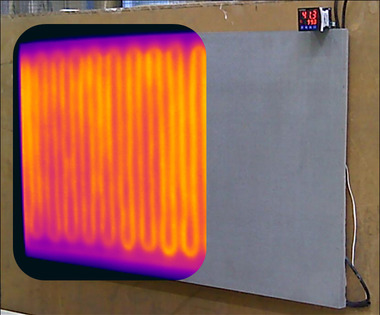

The Space Eye is an extraordinary project, for whose planning and design the architect Mario Botta was chosen. Classic steel reinforcement has been replaced by slender carbon reinforcement, which makes the concrete elements not only lighter, but also thinner. The construction thickness of the precast elements is only 50 mm. They were made by Element AG, at its plant in Tafers, Switzerland. The construction elements for the Space Eye were digitally planned in 3D and were made to measure before being transported to the construction site ready for installation. Element AG manufactured a total of 59 elements, which can be allocated to four different element groups: façade elements, base elements, floor elements and end elements. The 32 façade elements were manufactured in nine different dimensions. After having been transported from the plant to the construction site, located at an elevation of 95 meters above sea level, the construction elements were lifted with great precision into the final position and installed. From the groundbreaking ceremony to the opening of the observatory, barely a year passed, which emphasizes once again the well-known strengths of precast concrete elements: short construction times and on-schedule completion.

Flagship project of Element AG

Element AG is a leading precast concrete manufacturer in Switzerland. Resource-preserving building – enabled by use of the latest technologies and approaches – is for the manufacturer an integral part of its corporate philosophy. For Element AG, the Space Eye is a flagship project to demonstrate its capability for sustainable building.

Beton Bauteile 2025

The complete project report can be read in the yearbook “Beton Bauteile 2025.” The yearbook is an inspirational reference book on exceptional projects, aesthetics and the art of engineering with precast concrete elements. Numerous contributions in the chapters on architecture, technical construction, infrastructure, garden and landscape construction and – this year, for the first time, additive building – showcase the universal usability of the products as well as innovations and trends.

You can obtain your copy online at the Bauverlag Shop and via this link: www.beton-bauteile.de.