High-performance insulation materials in precast elements – architecture for slender and efficient solutions

A high-performance insulating board made of Resol rigid foam revolutionizes construction with precast concrete elements.

What – in terms of production engineering – are the benefits of Kooltherm K20 compared to other insulation solutions?

Kooltherm K20 can provide precast elements with high-efficiency insulation extremely fast, and at the same time cost efficient. Owing to the extraordinary insulation properties of the board, higher energy-efficient classes can be achieved with standard wall thickness.

And apart from production?

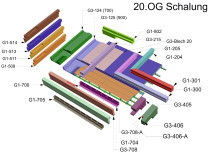

Kooltherm K20 insulation boards can be very flexibly used and adapted to any architectural precast element design without any problem. The extremely thin design of Kooltherm K20 minimizes the space required by the insulation boards and/or the precast elements – both during storage and transport.

Kooltherm K20 – the “concrete gold” insulation –

tightly calculated space gain

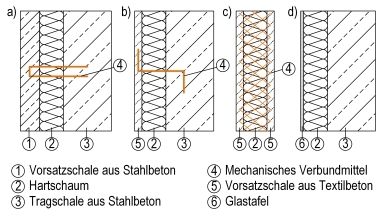

Surface area and space are today more valuable than ever. Whether for newbuilds or refurbishment projects: every square meter counts and pays off. The building shell plays a central role here. Kooltherm K20 makes possible sandwich wall systems up to 30 % thinner, which enables enormous space savings.

The advantages of the innovative Kooltherm K20 insulation board made of rigid Resol foam at a glance:

Enables hghly efficient precast element production enabled

Nearly unlimited freedom of design

Top insulation values / lambda value of up to λD= 0.021 W/(m·K)

Extreme thinness and extremely high performance

Sandwich wall construction of reduced thinness with the same energy efficiency compared to conventional insulation materials

Enormous space gain

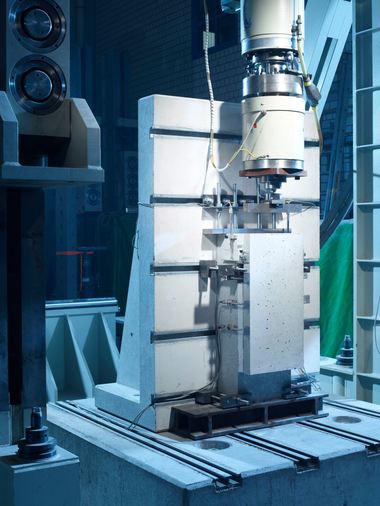

High compressive strength

Safety due to high fire protection, C-s1, d0

Sustainability is the mission at Kingspan:

Within the scope of our initiative “Planet Passionate” we are determined to reduce our carbon emissions (CO2) in production to zero, and to halve carbon intensity in our primary delivery chain. Our 10-year plan is dedicated to four key topics: energy, carbon, circularity, water.